Steel Sheet Insights & Buyer's Guide

Steel sheets are materials used in countless industries, providing strength, versatility, and cost-effectiveness. This article seeks to explore the wide-ranging world of steel sheets, covering the processes of manufacture, the various types available, and their diverse applications. From the point of production in the mill to their end use in building components or automotive parts, it is important to understand the properties and applications of different steel sheets for engineers, designers, and basically everyone associated with construction or manufacturing.

For more in-depth information you should view from Top steel sheet Manufacturers in China - Dapu Metal

Types of Steel Sheets

Hot Rolled Steel Sheets

Hot-rolled steel sheets are produced by rolling steel at high temperatures. This steel sheet usually has a rough surface finish with less precise dimensions when compared with a cold-rolled steel. Hot rolling cools down and makes the steel easier to work with, so different shapes can be made out of it. In applications where surface finish and dimensional accuracy are not critical, one hundred percent of the hot-rolled steel sheets attract a far lower price. ASTM specifications such as A1011 usually specify their material quality and mechanical properties. Available in various thicknesses, these sheets find applications in tank construction and raw materials where strength is more important than appearance. Some consideration must be given to asking for a quote and knowing what selection options are available when buying hot-rolled steel.

Cold Rolled Steel Sheets

Cold-rolled steel sheets are manufactured by processing the steel at room temperature, after the steel cools following the hot rolling process. This method informs that the silicon increases in strength of the material, surface finish, and dimensional accuracy. Cold-rolled sheets are generally thin and smooth to the touch, granting a uniform look. This contrasts with their counterparts, which normally have fewer beauty and tighter tolerance requirements, such as in furniture, home appliances, and automotive components.

The other added advantage in the cold rolling method is the improvement of the mechanical properties of the steel, such as tensile strength and hardness. Therefore, the usage of cold-rolled steel in strong and yet light applications for which this steel has been designed is working well for those areas. Further, their surface quality is good, which makes processes like stamping, bending, and welding easier to be performed on the cold-rolled sheets.

Cold rolled steel sheets are manufactured to different grades and finished matte or bright, or with a mirror finish, with respect to the requirements of the project itself. Custom thickness and dimensions can always be ordered for special needs. When choosing cold-rolled steel sheets for products, considering yield strength, elongation, surface treatment such as galvanization, or a coating that will ensure durability will be very good.

Stainless Steel Sheets

Stainless steel sheets are extremely desirable for their corrosion resistance and are therefore ideal for all sorts of applications in harsh environments. Their value lies in their durability and low-maintenance qualities, and several grades exist that suit various end uses. Stainless steel sheets find applications in:

Kitchen appliances

Medical equipment

Chemical process tanks

Architectural cladding

Custom cutting services are available from a number of suppliers. In stainless steel sheets, the material type, surface finish, and thickness should at all times be considered. A steel sheet calculator can help determine the amount of steel required for a particular job.

Manufacturing Processes for Steel Sheets

Overview of Steel Sheet Production

The manufacturing of a steel sheet is a complex set of operations starting from the steel mill, with the raw materials, first of all, being the principal elements for the production of molten steel. The creation of steel is followed by the casting of molten steel into large slabs or large billets, which are then rolled into thinner sheets. The sheets have to be rolled to thin them out and reveal the form of the sheets. The product's final quality depends of prime importance on temperature, pressure, and speed control during the manufacturing process. Continuous improvements are therefore necessary to maintain the value and competitive pricing of steel sheets. In turn, the steel sheet manufacturing industry keeps evolving toward newer technologies with better quality and service improvements.

Hot Rolling v. Cold Rolling

These two major methods used to produce steel sheets differ because they impart different properties to the metal. Hot rolling is steel processing at elevated temperatures, usually above the temperature of recrystallization, to enable it to be formed and shaped into sheets. Since it is cheaper, it leads to a rough surface and less accurate dimensions. Cold rolling, conversely, is done at ambient temperature, which generally imparts more strength and hardness to steel and also improves surface finish. For any given application, one may have to decide between hot-rolled and cold-rolled steel sheets, with cold-rolled usually being preferred in high-precision applications but at a higher price. Check with your steel supplier what types are available and how these two rolling methods affect steel sheet characteristics.

Steel Sheet Manufacturing: Quality Control

The quality control of steel sheet manufacturing assures that what is supplied meets the required product specification and ASTM standards. Testing and inspections are carried out during all stages of production, starting from raw materials through intermediate products and ultimately at the final stage of manufacture. Dimensional accuracy, surface finish, mechanical properties, and chemical composition are, therefore, all checked. Non-destructive testing, like ultrasonic testing, is conducted to check for internal faults. Statistical process control (SPC) is adopted to ensure constant variation in the properties of steel sheets. A steel sheet calculator helps determine the appropriate steel thickness for a particular project. Getting a quote from the supplier is a must, along with understanding their quality assurance procedures, whenever buying steel sheet.

Applications of Steel Sheet Among Various Sectors

Construction and Architecture

In the construction and architectural sectors, the use of steel sheets is immense owing to their structural integrity and versatility. Steel sheets constitute the building framework, roofing, and cladding, wherein their very strength and durability ensure a long-lasting performance. The value of steel as a construction material lies in the fact that it can withstand huge loads and environmental stress with the easy assurance of the safety of the structure and longevity for the project. Depending upon the requirements of the project and environmental conditions, different types of steel are chosen. The availability of cut-to-size services further increases the utility of steel sheets in custom architectural design. Using a steel sheet calculator can help in measuring the exact thickness needed for an application, thus reducing wastage and costs. Ask your supplier for a quote to get the best price.

Uses for the Automotive Industry

Steel sheets are heavily used by the automotive industry for vehicle bodies, chassis members, and some structural parts. The excellent strength-to-weight ratio of steel sheets ensures the safety and fuel efficiency of vehicles. They employ both hot- and cold-rolled steels in the making of vehicles and select them on the basis of properties suitable for a job and costs. Steel sheets can be formed into complex shapes and designs to increase the aesthetic appeal and aerodynamic superiority of vehicles. While aluminum is often looked upon as an alternative, steel still presents an economical solution for a number of applications. Quality control must be maintained to ensure the steel sheets conform to stringent ASTM standards for safety and performance. The industry greatly benefits from the value and versatility that steel sheets offer for car production. Steel sheet constitutes much of the raw structure of a car, so quality is very important.

Manufacturing and Fabrication

From manufacturing and fabrication, we see steel sheets as quintessential materials used in the making of a wide variety of products ranging from appliances to industrial equipment. Their formability, weldability, and strength are the reasons for their diverse applicability. Steel is flexible to fabricate in several ways involving shaping, cutting, joining, etc., giving it an edge in design and production. With the availability of different types of steel sheets, including stainless steel and coated steel, manufacturers can select the most suitable for the purpose at hand. Metal fabrication shops usually provide cut-to-size services to lessen the waste and maximize the use of material. Purchasing steel sheets online from a trusted supplier further guarantees a steady supply of quality materials. Planning your manufacturing project while requesting a quote will be helpful in price comparison and regarding the cost-effectiveness of steel sheets. Fabrication of metal sheets is very common for manufacturing equipment.

Maintenance and Care for Steel Sheets

Cleaning and Preventing Corrosion

The integrity of a steel sheet must be preserved by means of cleaning and corrosion prevention strategies. Steel sheets should be cleaned regularly to remove dust and dirt and prevent corrosion from setting in. The correct maintenance can prevent the quality degradation of steel. Some of the protection techniques are:

These layers of protective coatings, including paints or anti-rust treatments, bestow a barrier against moisture or harsher chemical elements.

Depending on the nature of steel, cleaners must be chosen that will not destroy the beauty of its surface finish. Stainless steel sheets, for example, may require special cleaners to protect their corrosion resistance. Galvanized steel sheets come with a protective zinc layer, though sometimes further treatment might be warranted in a harsher environment.

Preventive measures will enhance the utility and life of metal sheets. This maintenance is very important to ensure long-term durability and adequate aesthetic appearance.

Storage Solutions for Steel Sheets

Correct storage will destroy any possibilities of steel sheet damage and preserve its quality. The ideal storage must protect the metal sheets from moisture, humidity, and any physical damage. Indoor storage is preferred. However, if the storage has to be outdoors, then it must be covered with waterproof tarpaulins, preventing rust formations. Proper stacking of steel sheets using wooden skids or supports prevents bending and deformation. Also, different types of steel should be separated to avoid galvanic corrosion. This happens when two dissimilar metals come into contact via an electrolyte. Efficient storage methods maintain the value of the steel sheets and reduce expensive replacements. Think about cutting to size to better suit the storage. This way, the material will be maintained in top-notch condition, ready for use in a project.

Recognizing Signs of Wear and Tear

Early recognition of wear and tear signs and their maintenance can prevent more damage from occurring to steel sheets. Regular inspection should search for the presence of rust, dents, scratches, or any other sign of damage. Rust usually signals corrosion that might affect beyond repair the structural strength of the steel. Dents and scratches might impair the strength of the metal and create doorways for moisture to hasten the corrosion process. Warping or bending might suggest stress or overloading of the structure. Immediate steps will prevent further damage and increase the lifespan of the steel sheets. A steel sheet calculator could assist in determining whether the remaining thickness of steel following wear and tear is enough for its intended application. Prompt action will add value to the steel sheet, and the action might be averted as a great safety hazard. Check the surface finish for any irregularities.

Frequently Asked Questions (FAQs)

What are the benefits of using steel sheet material?

Steel sheet is known for its strength and durability, perfect for many applications. The versatility of metal sheets allows their use in construction, automotive, and manufacturing industries. Secondary to that, steel sheets tend to be generally less costly than aluminum or other materials in larger-scale projects. Other factors that work toward their virtues include quality and corrosion resistance. When weighing options, steel sheets provide worthwhile benefits in longevity and performance.

How is the price of steel sheets determined?

The price of steel sheets is influenced by several factors, including demand in the market, thickness, and quality of the material. Prices may fluctuate due to variations in the cost of raw materials and production processes. Also, different grades of steel, such as A1011, might carry different price tags depending on their characteristics and intended uses. Generally, the highest possible discount is given for quoted bulk orders; thus, suppliers must be compared so as to procure a better price. Knowing the pricing gives an informed view so as to make wise choices for project purchases.

What thickness options are available for metal sheets?

Metal sheets, including steel ones, come in assorted thicknesses to be used for different applications. It can be any thickness from very light gauge to heavy gauge plate. The thickness greatly changes the strength, weight, and price of the sheet. Consider the load-bearing and fabrication requirements of the project in determining the appropriate thickness. Many suppliers do provide custom thicknesses upon request.

Can I get fast delivery for steel sheets?

From a hurried project perspective, quick delivery is arguably the crucial stage anywhere within the supply chain, as such is offered by numerous suppliers for metal sheets. Quick shipping may, at times, depend on the producer's availability of stock as well as the order's individual specifications. When placing an order, it is best to inform the supplier of your schedule and ask for expedited services. There may also be options for pre-cut sizes or standard dimensions. Ensuring that your supplier can provide that fast turnaround will keep you on your schedule.

What tools are needed to work with steel sheets?

Steel sheet operations require specific tools to ensure safety during cutting, shaping, and installation. Usually used are sheets or metal shears, plasma cutters, and welding equipment. For small projects, tin snips and angle grinders will do. The choice of the tool will depend on the thickness of the sheet and the complexity of the process. Protective gear for the handler should include the use of gloves and safety glasses, so as to prevent any injuries.

254SMO Stainless Steel Sheet, Customizable. S31254 Hot-rolled Steel Sheet for Chemical Containers, ASTM A240.NegotiableMOQ: 100 KilogramsType: Steel PlateCertification: ISOTechnique: Other, hot/cold rolled forgedApplication: Mold & Dies, Ship Plate, Boiler Plate, Container Plate, Flange PlateJiangsu Zhonggongte Metallurgical Technology Co., Ltd.1 Yr

254SMO Stainless Steel Sheet, Customizable. S31254 Hot-rolled Steel Sheet for Chemical Containers, ASTM A240.NegotiableMOQ: 100 KilogramsType: Steel PlateCertification: ISOTechnique: Other, hot/cold rolled forgedApplication: Mold & Dies, Ship Plate, Boiler Plate, Container Plate, Flange PlateJiangsu Zhonggongte Metallurgical Technology Co., Ltd.1 Yr Wholesale Hot Rolled A36 A53 A283 Alloy Mild Carbon Steel SheetNegotiableMOQ: 100000 TonsType: Stainless Steel FlatsCertification: ISO, ROHS, ASTM, JISShape: FlatGrade: 500 SeriesZhongzheng Stainless Steel Co., Ltd.1 Yr

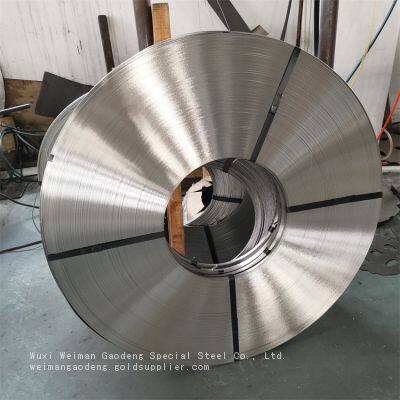

Wholesale Hot Rolled A36 A53 A283 Alloy Mild Carbon Steel SheetNegotiableMOQ: 100000 TonsType: Stainless Steel FlatsCertification: ISO, ROHS, ASTM, JISShape: FlatGrade: 500 SeriesZhongzheng Stainless Steel Co., Ltd.1 Yr 309S S32304 Stainless Steel Sheet & Strip - Kiln High-Heat AnnealedNegotiableMOQ: 10 KilogramsType: Other, Stainless Steel Plate, Sheet, and StripCertification: ISO, AISI, ASTM, GB, EN, JISShape: FlatGrade: OtherWuxi Weiman Gaodeng Special Steel Co., Ltd.1 Yr

309S S32304 Stainless Steel Sheet & Strip - Kiln High-Heat AnnealedNegotiableMOQ: 10 KilogramsType: Other, Stainless Steel Plate, Sheet, and StripCertification: ISO, AISI, ASTM, GB, EN, JISShape: FlatGrade: OtherWuxi Weiman Gaodeng Special Steel Co., Ltd.1 Yr Chute Fabricated Wear Plate Liner Hardfacing Steel Sheet/plateUS$ 100 - 300MOQ: 1 Square MeterBrand Name: WODONPlace of Origin: ChinaLength: 3000mm, 3400mm, 3500mm, customizedType: Steel PlateJiangsu Wodon Wear Resistant New Material Co., Ltd.1 Yr

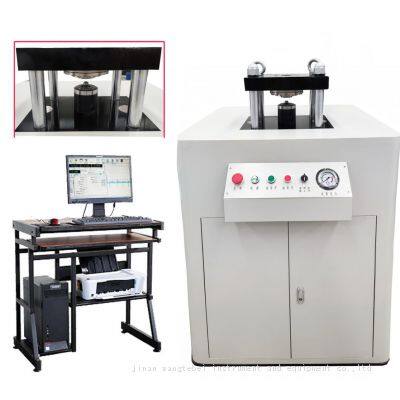

Chute Fabricated Wear Plate Liner Hardfacing Steel Sheet/plateUS$ 100 - 300MOQ: 1 Square MeterBrand Name: WODONPlace of Origin: ChinaLength: 3000mm, 3400mm, 3500mm, customizedType: Steel PlateJiangsu Wodon Wear Resistant New Material Co., Ltd.1 Yr Portable Cupping Tester Steel Sheet Cupping Testing Machine Aluminum Sheet Cupping TesterUS$ 12000 - 17000MOQ: 1 SetType: Other, cupping testing machineWeight: 100-500KgPower Source: AC380VAccuracy Grade: 1Jinan Wangtebei Instrument And Equipment Co.,ltd1 Yr

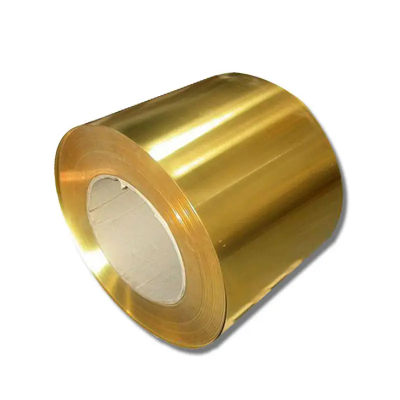

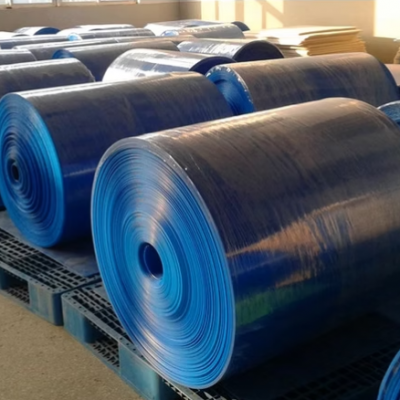

Portable Cupping Tester Steel Sheet Cupping Testing Machine Aluminum Sheet Cupping TesterUS$ 12000 - 17000MOQ: 1 SetType: Other, cupping testing machineWeight: 100-500KgPower Source: AC380VAccuracy Grade: 1Jinan Wangtebei Instrument And Equipment Co.,ltd1 Yr SPCC Tinplate Tinned Steel Sheet Coil for SaleUS$ 810 - 823MOQ: 25 TonsType: Other, electrolytic tinplate steel coilCertification: ISOTechnique: Hot RolledApplication: Mold & Dies, Ship Plate, Boiler Plate, Container Plate, Flange PlateShandong Sino New Material Co., Ltd.1 Yr

SPCC Tinplate Tinned Steel Sheet Coil for SaleUS$ 810 - 823MOQ: 25 TonsType: Other, electrolytic tinplate steel coilCertification: ISOTechnique: Hot RolledApplication: Mold & Dies, Ship Plate, Boiler Plate, Container Plate, Flange PlateShandong Sino New Material Co., Ltd.1 Yr Wholesale Vinyl Seawall Sheet Piling Prices Plastic Steel Sheet PileUS$ 19.90 - 39.90MOQ: 100 MetersPlace of Origin: Zhejiang, ChinaBrand Name: SmalbossModel Number: SU718Tongxiang Small Boss Special Plastic Products Co.,Ltd.1 Yr

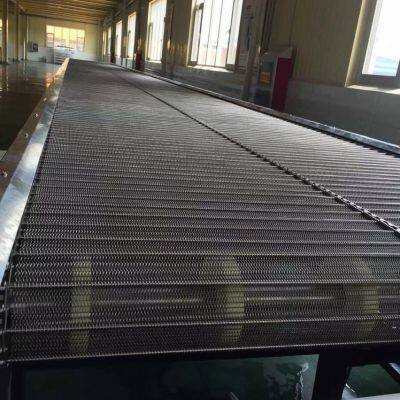

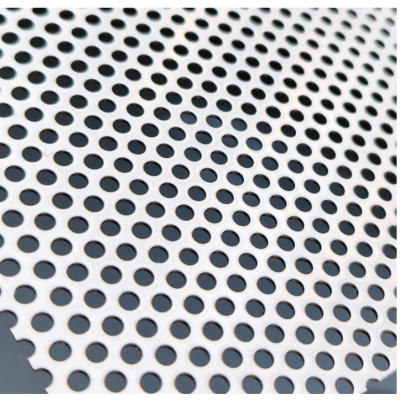

Wholesale Vinyl Seawall Sheet Piling Prices Plastic Steel Sheet PileUS$ 19.90 - 39.90MOQ: 100 MetersPlace of Origin: Zhejiang, ChinaBrand Name: SmalbossModel Number: SU718Tongxiang Small Boss Special Plastic Products Co.,Ltd.1 Yr Vertical Arrangement Perforated Stainless Steel Sheet Stainless Steel Mesh ScreenUS$ 3.99 - 4.99MOQ: 50 Square MetersApplication: FilterTechnique: PerforatedHebei Longen Wire Mesh Products Co., Ltd.1 Yr

Vertical Arrangement Perforated Stainless Steel Sheet Stainless Steel Mesh ScreenUS$ 3.99 - 4.99MOQ: 50 Square MetersApplication: FilterTechnique: PerforatedHebei Longen Wire Mesh Products Co., Ltd.1 Yr Galvanized Steel Sheet C Stud Wall Channel for Dry ConstructionNegotiableMOQ: 5000 PiecesMaterial: Other, Hot Dipped GalvanizedCertification: ISO9001Shape: C-typeFunction: Sound Proof, Fireproofing, Jar-Proof, Anti-Corrosion, Damp-ProofShanxi Pano Building Materials Co., Ltd1 Yr

Galvanized Steel Sheet C Stud Wall Channel for Dry ConstructionNegotiableMOQ: 5000 PiecesMaterial: Other, Hot Dipped GalvanizedCertification: ISO9001Shape: C-typeFunction: Sound Proof, Fireproofing, Jar-Proof, Anti-Corrosion, Damp-ProofShanxi Pano Building Materials Co., Ltd1 Yr Heavy Metal Shredder Stainless Steel Sheets Auto Parts Crusher MachineUS$ 18600MOQ: 1 SetMaterial: Alloy SteelCertification: CE, ISODrive: ElectricUsage: MetalHenan Walle Industry Co., Ltd1 Yr

Heavy Metal Shredder Stainless Steel Sheets Auto Parts Crusher MachineUS$ 18600MOQ: 1 SetMaterial: Alloy SteelCertification: CE, ISODrive: ElectricUsage: MetalHenan Walle Industry Co., Ltd1 Yr Stainless Steel Sheet Bumper Stamping Parts High PrecisionNegotiableMOQ: 100 PiecesBrand Name: JunzhuPlace of Origin: ChinaPlastic Modling Type: StampingShijiazhuang Junzhu Technology Co., Ltd1 Yr

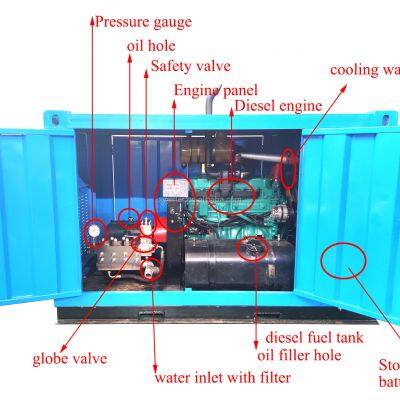

Stainless Steel Sheet Bumper Stamping Parts High PrecisionNegotiableMOQ: 100 PiecesBrand Name: JunzhuPlace of Origin: ChinaPlastic Modling Type: StampingShijiazhuang Junzhu Technology Co., Ltd1 Yr China Water Jetting Machine High Pressure Auxiliary Steel Sheet Pile Hole PilingUS$ 12000.00MOQ: 1 Setmachine type: HIGH PRESSURE CLEANERcondition: Newplace of origin: shenyang, Chinabrand name: RELIABLEShenyang Reliable Technology Co., Ltd.1 Yr

China Water Jetting Machine High Pressure Auxiliary Steel Sheet Pile Hole PilingUS$ 12000.00MOQ: 1 Setmachine type: HIGH PRESSURE CLEANERcondition: Newplace of origin: shenyang, Chinabrand name: RELIABLEShenyang Reliable Technology Co., Ltd.1 Yr The Steel Sheet Pile Driver Used in the New Excavator Has Low Noise and High EfficiencyUS$ 15000 - 15000MOQ: 1 SetHS Electrical Technology Co,LTD3 Yrs

The Steel Sheet Pile Driver Used in the New Excavator Has Low Noise and High EfficiencyUS$ 15000 - 15000MOQ: 1 SetHS Electrical Technology Co,LTD3 Yrs Galvanized Steel Perforated Metal Sheet/ Perforated Metal Mesh,Hot Galvanizing Perforated Plate Sheets. BOLI PERFORATEDUS$ 10MOQ: 10 FeetMaterial: Steel plateWarranty: 10 YEARWeight: Middle-weightApplication: Construction Wire Mesh, Protecting Mesh, Decorative MeshAnping Boli Wire Mesh Hardware Co.,ltd2 Yrs

Galvanized Steel Perforated Metal Sheet/ Perforated Metal Mesh,Hot Galvanizing Perforated Plate Sheets. BOLI PERFORATEDUS$ 10MOQ: 10 FeetMaterial: Steel plateWarranty: 10 YEARWeight: Middle-weightApplication: Construction Wire Mesh, Protecting Mesh, Decorative MeshAnping Boli Wire Mesh Hardware Co.,ltd2 Yrs Polypropylene Corrugated Sheets – Protective for Steel Coils PackingNegotiableMOQ: 3000 PiecesMaterial: PPColor: BlackKind: Engineering Plastic SheetOrigin: ChinaZibo Shichuang Composite Materials Co., Ltd.1 Yr

Polypropylene Corrugated Sheets – Protective for Steel Coils PackingNegotiableMOQ: 3000 PiecesMaterial: PPColor: BlackKind: Engineering Plastic SheetOrigin: ChinaZibo Shichuang Composite Materials Co., Ltd.1 Yr Vegetable Sheet Cutter Processing Machine Fruits Cube Cutting With Food SteelNegotiableMOQ: 1 SetBrand Name: GELGOOGPlace of Origin: ChinaModel Number: GG-312Type: Other, JuicerHenan Gelgoog Machinery CO,LTD2 Yrs

Vegetable Sheet Cutter Processing Machine Fruits Cube Cutting With Food SteelNegotiableMOQ: 1 SetBrand Name: GELGOOGPlace of Origin: ChinaModel Number: GG-312Type: Other, JuicerHenan Gelgoog Machinery CO,LTD2 Yrs SCAIR 40HP Stainless Steel Refrigeration Unit Outer Box Stainless Steel Water Tank Sheet Metal Manufacturer SC-40WUS$ 4800 - 196000MOQ: 1 PieceBrand Name: SCAIRPlace of Origin: ChinaModel Number: water chillers industrialCertification: CEDongguan Shun Chi Mechanical And Electrical Equipment Co. , Ltd.3 Yrs

SCAIR 40HP Stainless Steel Refrigeration Unit Outer Box Stainless Steel Water Tank Sheet Metal Manufacturer SC-40WUS$ 4800 - 196000MOQ: 1 PieceBrand Name: SCAIRPlace of Origin: ChinaModel Number: water chillers industrialCertification: CEDongguan Shun Chi Mechanical And Electrical Equipment Co. , Ltd.3 Yrs POM FM025UV Formosa Steel UV Resistant Grade High Rigidity Sheet and Rod FM090 Pom Raw MaterialUS$ 1 - 2MOQ: 55 PoundsBrand Name: FORMOCONPlace of Origin: ChinaModel Number: FM025UVShanghai Lechangrong Plastics Co., Ltd.1 Yr

POM FM025UV Formosa Steel UV Resistant Grade High Rigidity Sheet and Rod FM090 Pom Raw MaterialUS$ 1 - 2MOQ: 55 PoundsBrand Name: FORMOCONPlace of Origin: ChinaModel Number: FM025UVShanghai Lechangrong Plastics Co., Ltd.1 Yr Stainless Steel Pvc Pet Crushing Sheet Cleaning Dryer Plastic Particle Dehydrator for SaleNegotiableMOQ: 1 SetPlace of Origin: ChinaAfter-sales Service Provided: Engineers available to service machinery overseasApplication: Plastic recycling industry, in ABS, PS separation and PET bottle recyclingCondition: NewDongguan Xinbao Machinery Co., Ltd1 Yr

Stainless Steel Pvc Pet Crushing Sheet Cleaning Dryer Plastic Particle Dehydrator for SaleNegotiableMOQ: 1 SetPlace of Origin: ChinaAfter-sales Service Provided: Engineers available to service machinery overseasApplication: Plastic recycling industry, in ABS, PS separation and PET bottle recyclingCondition: NewDongguan Xinbao Machinery Co., Ltd1 Yr POM FM025UV Formosa Steel UV Resistant Grade High Rigidity Sheet and Rod FM090 Pom Raw MaterialUS$ 1.1 - 1.3MOQ: 25 KilogramsBrand Name: FORMOCONPlace of Origin: Taiwan, ChinaModel Number: FM025UVDenyslcal: 1.41g/cmShanghai Liangrun International Trade Co., Ltd.1 Yr

POM FM025UV Formosa Steel UV Resistant Grade High Rigidity Sheet and Rod FM090 Pom Raw MaterialUS$ 1.1 - 1.3MOQ: 25 KilogramsBrand Name: FORMOCONPlace of Origin: Taiwan, ChinaModel Number: FM025UVDenyslcal: 1.41g/cmShanghai Liangrun International Trade Co., Ltd.1 Yr Outdoor Wall Panel Metal Steel Fence Iron Sheet Aluminum Zinc Plated FenceNegotiableMOQ: 100 Square MetersMaterial: MetalSurface Treatment: CoatedAnping Dingdian Wire Mesh Products Co., Ltd.1 Yr

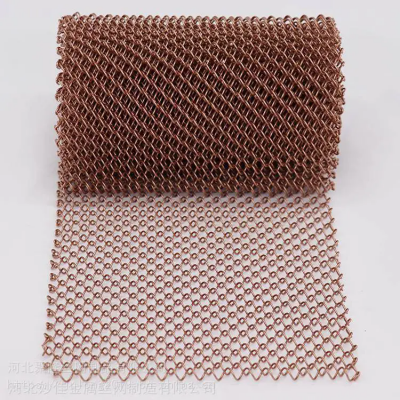

Outdoor Wall Panel Metal Steel Fence Iron Sheet Aluminum Zinc Plated FenceNegotiableMOQ: 100 Square MetersMaterial: MetalSurface Treatment: CoatedAnping Dingdian Wire Mesh Products Co., Ltd.1 Yr Bright 304 316 316L Stainless Steel Woven Wire Mesh Sheet for Decoration Curtain WallNegotiableMOQ: 50 Square MetersTechnique: WovenWeave Technique: Twill WeaveMaterial Type: Stainless Steel WireType: Stainless Steel Plain Wire MeshHebei Julong Wire Mesh Co., Ltd.1 Yr

Bright 304 316 316L Stainless Steel Woven Wire Mesh Sheet for Decoration Curtain WallNegotiableMOQ: 50 Square MetersTechnique: WovenWeave Technique: Twill WeaveMaterial Type: Stainless Steel WireType: Stainless Steel Plain Wire MeshHebei Julong Wire Mesh Co., Ltd.1 Yr Buyer is sourcing satin bronze stainless steel sheets43 minutes ago

Buyer is sourcing satin bronze stainless steel sheets43 minutes ago Operations Head requested a quote for Straightening rolls for steel sheets2025-11-15 06:24:30

Operations Head requested a quote for Straightening rolls for steel sheets2025-11-15 06:24:30 Procurement Lead requested a quote for stainless steel sheet metal2025-11-15 01:24:04

Procurement Lead requested a quote for stainless steel sheet metal2025-11-15 01:24:04 Lead Purchaser placed an order for Galvanized steel sheet2025-11-11 22:15:05

Lead Purchaser placed an order for Galvanized steel sheet2025-11-11 22:15:05 Purchasing Director verified certifications for Customized Steel and stainless steel Sheet Metal Fabrication2025-11-15 21:41:44

Purchasing Director verified certifications for Customized Steel and stainless steel Sheet Metal Fabrication2025-11-15 21:41:44 Steel SheetUS$ 600 - 800MOQ: 1 TonStandard: AISI, ASTM, BS, DIN, GB, JISGrade: Q235B/Q345B/Q345C/S235 JR/S27Thickness: 1mm - 100mmPlace of Origin: Shanghai, ChinaTianjin TEDA YADA Steel Co., Ltd.5 Yrs

Steel SheetUS$ 600 - 800MOQ: 1 TonStandard: AISI, ASTM, BS, DIN, GB, JISGrade: Q235B/Q345B/Q345C/S235 JR/S27Thickness: 1mm - 100mmPlace of Origin: Shanghai, ChinaTianjin TEDA YADA Steel Co., Ltd.5 Yrs 1.4876 Steel Steel SheetUS$ 3,000 - 3,800MOQ: 1 TonBrand Name: CunRuiPlace of Origin: Jiangsu, ChinaModel Number: 1.4876Certification: ISOJiangsu Cunrui Metal Products Co., Ltd.5 Yrs

1.4876 Steel Steel SheetUS$ 3,000 - 3,800MOQ: 1 TonBrand Name: CunRuiPlace of Origin: Jiangsu, ChinaModel Number: 1.4876Certification: ISOJiangsu Cunrui Metal Products Co., Ltd.5 Yrs Steel Sheet PilingUS$ 600 - 900MOQ: 10 TonsBrand Name: BOCHIPlace of Origin: Chongqing, ChinaModel Number: U, Z, Corner sheet pileStandard: AISI, ASTM, BS, DIN, GB, JISBochi Corporation5 Yrs

Steel Sheet PilingUS$ 600 - 900MOQ: 10 TonsBrand Name: BOCHIPlace of Origin: Chongqing, ChinaModel Number: U, Z, Corner sheet pileStandard: AISI, ASTM, BS, DIN, GB, JISBochi Corporation5 Yrs Stainless Steel Sheet for ElevatorUS$ 1,200 - 2,500MOQ: 100 TonsBrand Name: RenDa, RendaPlace of Origin: ChinaModel Number: 304, 0.12-2.0mm*600-1250mmLength: 1000mm-8000mmShandong Renda International Trade Co., Ltd.5 Yrs

Stainless Steel Sheet for ElevatorUS$ 1,200 - 2,500MOQ: 100 TonsBrand Name: RenDa, RendaPlace of Origin: ChinaModel Number: 304, 0.12-2.0mm*600-1250mmLength: 1000mm-8000mmShandong Renda International Trade Co., Ltd.5 Yrs Steel Sheet Custom FabricationUS$ 2,000 - 3,500MOQ: 1Brand Name: CustomPlace of Origin: Fujian, ChinaModel Number: Custom partCNC Boring Mill Co., Ltd.5 Yrs

Steel Sheet Custom FabricationUS$ 2,000 - 3,500MOQ: 1Brand Name: CustomPlace of Origin: Fujian, ChinaModel Number: Custom partCNC Boring Mill Co., Ltd.5 Yrs Stainless Steel SheetsNegotiableMOQ: 10 PiecesPlace of Origin: ChinaModel Number: LS-08Foshan Longsailing Metal Products Co.,Ltd.5 Yrs

Stainless Steel SheetsNegotiableMOQ: 10 PiecesPlace of Origin: ChinaModel Number: LS-08Foshan Longsailing Metal Products Co.,Ltd.5 Yrs