Stainless Steel Insights & Buyer's Guide

Find the perfect combination of sophistication and utility in stainless steel. This extraordinary metal delivers excellent results in a wide range of applications because it combines aesthetic beauty with practicality. Stainless steel is unmatched due to its distinctive features, which make it highly desirable in various industries, whether in preparing a gourmet meal or constructing industrial machinery. Explore the realm of stainless steel and learn why it is so unique.

View stainless steel Manufacturers in China - Dapu Metal details

How is Stainless Steel Made?

What are the Components of Stainless Steel?

Stainless steel components widely used in construction have varying compositions depending on their application. Common additions include nickel, manganese, and molybdenum. Nickel compounds strengthen and form the metal, while also aiding in corrosion, and manganese contributes to alloy strength and ductility. All components work alongside to produce various types of stainless steel, including austenitic, ferritic, martensitic, and duplex stainless steels.

Why is it Called Stainless Steel?

Unlike metals like carbon steel, the term "stainless steel" was derived from the metal’s ability to resist corrosion and staining. The reason it does this so effectively lies in a passive layer of chromium oxide covering the metal's surface. This layer forms a protective shield from environmental factors that cause rust in other metals. As long as there is an adequate amount of chromium in the alloy, this protective layer can self-repair if damaged. This ensures a long lasting durability and shine of stainless steel.

What Role Does Nickel Play?

An essential element in the makeup and functionality of stainless steel is nickel, especially in austenitic grades, which exhibit high levels of strength and ductility. It not only further protects the alloy from corrosion but also keeps the stable austenitic phase intact, allowing the alloy to endure different temperatures and environments. Because of these reasons, stainless steel is preferred in many industries that require high-strength materials that can withstand harsh environments, such as in cookware, surgical devices, and structural components in buildings.

What are the Unique Properties of Stainless Steel?

How Does Chromium Oxide Prevent Rust?

Chromium, which is present in stainless steel, helps prevent rust. It creates a thin layer of chromium oxide when exposed to oxygen, which passively shields moisture and other destructive factors. Unlike painted or coated surfaces, chromium oxide is irrevocably bonded to the steel surface and can self-repair if scraped. Moreover, the oxide layer can be refreshed and is therefore waterproof and suitable for stainless steel, which tends to rust in tough environments.

What are the Mechanical Properties of Stainless Steel?

Stainless steeel has an impressive mechanical strength while also displaying toughness, high ductility, and flexibility. These factors vary across different grades, like ferritic or martensitic, which makes stainless steel so versatile. Unlike other metals used in construction or automotive parts, stainless steel can withstand significant force combined with impact and non-frequent wear, making it essential in engineering and manufacturing.

Why is Stainless Steel Corrosion-Resistant?

Stainless steel has many remarkable features but its ability to resist corrosion is one of the best traits. Protecting elements like nickel and molybdenum work together with steel's chromium to enable the unmatched protective durability which is the main cause why stainless steel is protected from corrosion.

The special mix allows stainless steel to endure contact with rusting chemicals, saltwater, and intense heat without undergoing the deterioration other metals do. For this reason, stainless steel is commonly used in naval technology, chemical processing equipment, and structures that endure severe weather.

How Does Stainless Steel Compare to Other Metals?

Stainless Steel vs. Carbon Steel: What are the Differences in Them?

The primary difference in stainless steel and carbon steel lies in their features and use. Carbon steel is made out of iron and carbon. It is very strong, but without the proper protection, carbon steel tends to rust and corrode. On the other hand, stainless steel has chromium which makes stainless steel possess excellent protection against rust and aid corrosion, which is a major environmental issue. This makes stainless steel more useful in areas where appearance, durability, and the steel's lifespan are needed or are a concern.

Does Stainless Steel Corrode Less Than Other Metals?

Yes, when comparing other metals, stainless steel possesses high corrosion resistance due to their chromium oxide layer. No metal can be 100% rust-free under any scenario, but in certain conditions, stainless steel outperforms other metals, such as galvanized steel or other alloys. This resistance helps the stainless steel products stay in good condition even after a long time.

Why Is Stainless Steel Better Than Other Alloys?

The combination of versatility, aesthetics, and reliability makes stainless steel stand out compared to other alloys. Due to its unparalleled corrosion resistance, ease of maintenance, and ability to retain structural integrity in extreme conditions, stainless steel is used in numerous industries, ranging from home kitchens to space exploration. Stainless steel also boasts easy recyclability, sustainable production methods, and environmental friendliness, aligning with modern values of sustainability and resourcefulness.

What are the Applications of Stainless Steel?

Stainless Steel Popular in Cookware

The popularity of stainless steel in cookware is because of its great durability, corrosion resistance, and non-reactiveness which protects flavors and nutrition during cooking. The metal's ability to evenly conduct heat with no hot spots enables precise temperature control, which further enhances the consistency of cooking results. Moreover, stainless steel cookware brings polish to kitchen décor, making it a practical choice as well as a design statement.

Stainless Steel in Industrial Applications

Stainless steel is an absolute need in an industrial setting owing to its ability to withstand brutal conditions and endure minimal care. It is used in the fabrication of machinery and storage tanks, as well as in structural components and other applications that require exceptional strength, resistance to high temperatures, and protection against corrosive substances. The robust properties of stainless steel makes it ideal for the chemical, petrochemical, and food processing industries where the equipment is subjected to rigorous operational demands.

Uses of Stainless Steel that Assist in Daily Life

The prevalence of stainless steel in daily life showcases its versatility and reliability. Its usage including cutlery and railings in homes and public places goes far beyond the industrial applications. From mobile phones to household items and even jewelry, we appreciate its beauty and utility. Because stainless steel retains its appeal over time, it is preferred for the construction of enduring and elegant products that seamlessly combine form and functionality.

How Does Stainless Steel Achieve Corrosion Resistance?

What Role Does Chromium Play in Corrosion Resistance?

Chromium is crucial in providing stainless steel its properties because it reacts with the oxygen in the environment forming a chromium oxide protective layer that keeps the stainless steel from rusting and corroding. This layer is self-healing, allowing the stainless steel to withstand the elements for a longer period. With an increased chromium content in the stainless steel alloy, the alloy becomes more resistant to rusting, and the self-healing layer becomes significantly more effective. This is the reason why environments with greater risk if corrosion are steel with high chromium content alloys.

How Does the Alloy Composition Affect Corrosion?

The molybdenum and nickel elements of the alloy have the most significant impact on the resistance of the region, thus assisting chromium in stainless steel alloys. Nickel mainly sustains the elasticity of the austenitic steel structure, which is key in extremely acidic or alkaline conditions, while also helping the weld region, thereby aiding resistance to pitting and crevice corrosion. A proper grade of steel is key to enhancing longevity and reliability, but to choose the right grade, one must consider all elements and how they affect and hinder the metal's attributes.

Can Stainless Steel Corrode Under Certain Conditions?

While extremely resistant, steel does not have absolute immunity to corrosion under certain conditions. Particular factors like long-term contact with highly acidic or chloride-filled settings can put stress on the protective chromium oxide layer. Focused austenitic and duplex stainless steels, resilient to corrosion, could be optimal choices in such cases. With proper guidance and consideration, the desired resilience can be achieved, prolonging the product’s durability and maintaining its aesthetic.

Frequently Asked Questions (FAQs)

Q: How is stainless steel made?

A: Stainless steel is made by melting iron ore and chromium together at high temperatures. The addition of chromium, at least 10.5%, creates a protective layer that prevents rusting. This process often includes other elements such as nickel, molybdenum, and nitrogen to enhance specific properties.

Q: What is the role of chromium in stainless steel?

A: Chromium is essential in creating stainless steel because it forms a thin layer of chromium oxide on the surface of the metal. This layer prevents further corrosion and gives stainless steel its characteristic resistance to rust and tarnishing. Typically, at least 10.5% chromium is required in the chemical composition to achieve this effect.

Q: What are the main types of stainless steel?

A: The main types of stainless steel include austenitic stainless steel, ferritic stainless steel, martensitic stainless steel, and precipitation hardening stainless steels. Each type has unique properties suited for various applications, based on their chemical composition and structure.

Q: Why is austenitic stainless steel so widely used?

A: Austenitic stainless steel is the most popular type because of its excellent corrosion resistance, versatility, and formability. It is non-magnetic and maintains its structure at both high and low temperatures, making it ideal for a wide range of applications. It is commonly recognized by its SAE steel grades, such as 304 and 316.

Q: How does heat treatment affect stainless steel?

A: Heat treatment can significantly alter the properties of stainless steel, including its hardness, strength, and resistance to wear. For example, martensitic stainless steel can be hardened through heat treatment, making it suitable for cutting tools and other applications requiring high strength.

Q: What distinguishes ferritic stainless steel from other types?

A: Ferritic stainless steel is characterized by its high chromium content and low carbon levels. It is magnetic, offers good resistance to stress corrosion cracking, and is generally less expensive than other types. However, it is less formable and weldable compared to austenitic stainless steel.

Q: Can stainless steel be recycled?

A: Yes, stainless steel is highly recyclable. Stainless steel scrap is collected and melted down to produce new stainless steel products. This process is energy-efficient and contributes to sustainable steel production by reducing the need for raw materials.

Stainless Steel HouseUS$ 10 - 120MOQ: 1 SetPlace of Origin: Shanghai, ChinaBrand Name: sinoarchModel Number: TE--0098Material: Other, Steel, SteelSinoarch Shanghai Co., Ltd.5 Yrs

Stainless Steel HouseUS$ 10 - 120MOQ: 1 SetPlace of Origin: Shanghai, ChinaBrand Name: sinoarchModel Number: TE--0098Material: Other, Steel, SteelSinoarch Shanghai Co., Ltd.5 Yrs Electric Wafer Butterfly Valve With Stainless Steel Disc & EPDM Seal for Industrial Fluid ControlNegotiableMOQ: 1 SetApplication: Industrial Usage, Water Industrial Usage, Household UsageOrigin: ChinaShanghai CAMP Environmental Protection Technology Co., Ltd.1 Yr

Electric Wafer Butterfly Valve With Stainless Steel Disc & EPDM Seal for Industrial Fluid ControlNegotiableMOQ: 1 SetApplication: Industrial Usage, Water Industrial Usage, Household UsageOrigin: ChinaShanghai CAMP Environmental Protection Technology Co., Ltd.1 Yr 304 Stainless Steel Light Duty Storage RackNegotiableMOQ: 1 SetUsage: IndustrialHeight: 0-5mClosed: OpenServiceability: Common UseGusu District Qiusheng Commercial Equipment Firm1 Yr

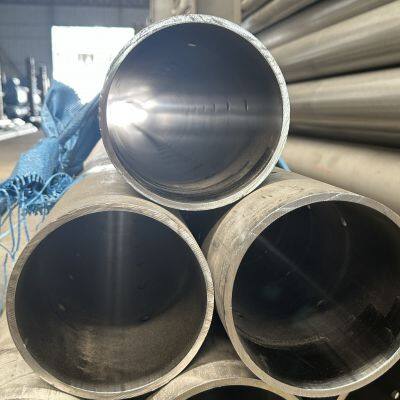

304 Stainless Steel Light Duty Storage RackNegotiableMOQ: 1 SetUsage: IndustrialHeight: 0-5mClosed: OpenServiceability: Common UseGusu District Qiusheng Commercial Equipment Firm1 Yr Made in China 2mm 3mm 6mm Metal Rod 201 304 310 316 316L Ba 2b Mirror Surface Stainless Steel Round Pipe With ISO9001, ASTM A269, GB, En, AISI,NegotiableMOQ: 100000 TonsType: SeamlessWarranty: 12 monthsTechnique: Cold DrawnSurface Treatment: PolishedZhongzheng Stainless Steel Co., Ltd.1 Yr

Made in China 2mm 3mm 6mm Metal Rod 201 304 310 316 316L Ba 2b Mirror Surface Stainless Steel Round Pipe With ISO9001, ASTM A269, GB, En, AISI,NegotiableMOQ: 100000 TonsType: SeamlessWarranty: 12 monthsTechnique: Cold DrawnSurface Treatment: PolishedZhongzheng Stainless Steel Co., Ltd.1 Yr 304 Stainless Steel Round Bar Silver Tone 6mm Diameter Polished Surface Industrial Stainless Steel RodNegotiableMOQ: 10 KilogramsType: Stainless Steel BarsCertification: ISO, ASTM, ENShape: RoundGrade: OtherWuxi Weiman Gaodeng Special Steel Co., Ltd.1 Yr

304 Stainless Steel Round Bar Silver Tone 6mm Diameter Polished Surface Industrial Stainless Steel RodNegotiableMOQ: 10 KilogramsType: Stainless Steel BarsCertification: ISO, ASTM, ENShape: RoundGrade: OtherWuxi Weiman Gaodeng Special Steel Co., Ltd.1 Yr 304, 304L, 321, 316L, 317L, 309s, 310s Inox Stainless Steel Pipe/Stainless Steel TubeNegotiableMOQ: 1 TonModel Number: 304, 304L, 321, 316L, 317L, 309s, 310sType: SeamlessApplication: Automotive, solar energy, metal products, household appliances, precision electronics, containers, machinery manufacturing, elevators, sanitary ware, rail transit, pressure vessels, architectural decoration, nuclear power, catering kitchenware, chemical equipment, daily electrical appliances, food machinery, structural pipe, etcStandard: ASTMJiangsu Zhonggongte Metallurgical Technology Co., Ltd.1 Yr

304, 304L, 321, 316L, 317L, 309s, 310s Inox Stainless Steel Pipe/Stainless Steel TubeNegotiableMOQ: 1 TonModel Number: 304, 304L, 321, 316L, 317L, 309s, 310sType: SeamlessApplication: Automotive, solar energy, metal products, household appliances, precision electronics, containers, machinery manufacturing, elevators, sanitary ware, rail transit, pressure vessels, architectural decoration, nuclear power, catering kitchenware, chemical equipment, daily electrical appliances, food machinery, structural pipe, etcStandard: ASTMJiangsu Zhonggongte Metallurgical Technology Co., Ltd.1 Yr Pneumatic Diaphragm Stainless Steel Control ValveNegotiableMOQ: 1 SetChangsong Industrial Equipment Shandong Ltd.2 Yrs

Pneumatic Diaphragm Stainless Steel Control ValveNegotiableMOQ: 1 SetChangsong Industrial Equipment Shandong Ltd.2 Yrs Stainless Steel Garbage Can Kitchen Dustbin Stainless Steel Princess PowderNegotiableMOQ: 1 PieceModel Number: A-661Place of Origin: ChinaFeature: Eco-FriendlyZhongshan ACEYEA Sanitary Ware Co., Ltd.1 Yr

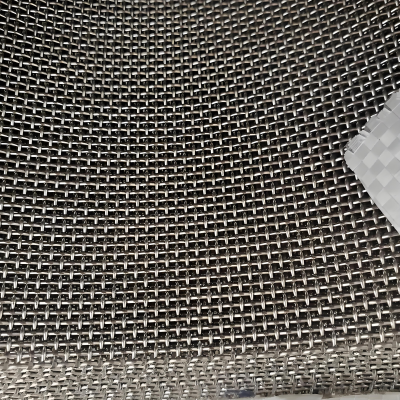

Stainless Steel Garbage Can Kitchen Dustbin Stainless Steel Princess PowderNegotiableMOQ: 1 PieceModel Number: A-661Place of Origin: ChinaFeature: Eco-FriendlyZhongshan ACEYEA Sanitary Ware Co., Ltd.1 Yr Stainless Steel Spring Wire Stainless Steel Wire Rope Mesh Stainless Steel Wire Mesh SheetUS$ 9.3 - 10MOQ: 1 MeterMaterial: SUS304Type: Stainless Steel Plain Wire MeshCertification: ISO9001, OtherWarranty: 10 yearsAnping Boli Wire Mesh Hardware Co.,ltd2 Yrs

Stainless Steel Spring Wire Stainless Steel Wire Rope Mesh Stainless Steel Wire Mesh SheetUS$ 9.3 - 10MOQ: 1 MeterMaterial: SUS304Type: Stainless Steel Plain Wire MeshCertification: ISO9001, OtherWarranty: 10 yearsAnping Boli Wire Mesh Hardware Co.,ltd2 Yrs Stainless Steel AISI 304 316 Wire Rope Mesh Railing Flexible Stainless Steel Wire Rope Mesh NetNegotiableMOQ: 50 Square MetersMaterial: Other, 304/316Type: Stainless Steel Plain Wire MeshApplication: Construction Wire Mesh, Protecting Mesh, Screen, Decorative Mesh, Fence MeshTechnique: WovenHebei Julong Wire Mesh Co., Ltd.1 Yr

Stainless Steel AISI 304 316 Wire Rope Mesh Railing Flexible Stainless Steel Wire Rope Mesh NetNegotiableMOQ: 50 Square MetersMaterial: Other, 304/316Type: Stainless Steel Plain Wire MeshApplication: Construction Wire Mesh, Protecting Mesh, Screen, Decorative Mesh, Fence MeshTechnique: WovenHebei Julong Wire Mesh Co., Ltd.1 Yr Quality Anti Corrosion New Fashion Stainless Steel Jewelry Necklace, Bracelet, Earring, Accessories, Rings Etc.NegotiableMOQ: 100 PiecesMaterial: Stainless SteelUsage: Decoration, GiftOccasion: Other, AllTrademark: OEMNantong Zhongmian Commercial Co., Ltd.1 Yr

Quality Anti Corrosion New Fashion Stainless Steel Jewelry Necklace, Bracelet, Earring, Accessories, Rings Etc.NegotiableMOQ: 100 PiecesMaterial: Stainless SteelUsage: Decoration, GiftOccasion: Other, AllTrademark: OEMNantong Zhongmian Commercial Co., Ltd.1 Yr Aluminium Stainless Steel Prod Vent Mush Marine Mushroom Cowl VentUS$ 440 - 440MOQ: 1 PieceWuxi Rongou Technology Development Co. Ltd.3 Yrs

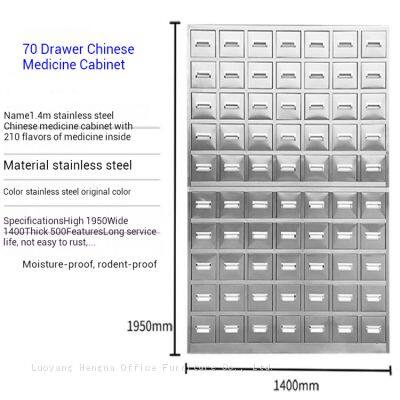

Aluminium Stainless Steel Prod Vent Mush Marine Mushroom Cowl VentUS$ 440 - 440MOQ: 1 PieceWuxi Rongou Technology Development Co. Ltd.3 Yrs Stainless Steel Chinese Medicine Cabinet OEM Factory|Stainless Steel Chinese Herbal Bucket Cabinet 1.2 m WideUS$ 50 - 300MOQ: 5 CombosMaterial: MetalStyle: ModernCondition: NewTransport Package: Carton BoxLuoyang Hengna Office Furniture Co., Ltd.1 Yr

Stainless Steel Chinese Medicine Cabinet OEM Factory|Stainless Steel Chinese Herbal Bucket Cabinet 1.2 m WideUS$ 50 - 300MOQ: 5 CombosMaterial: MetalStyle: ModernCondition: NewTransport Package: Carton BoxLuoyang Hengna Office Furniture Co., Ltd.1 Yr High Performance Stainless Steel Liquid Mixing BoilerNegotiableMOQ: 1 SetPlace of Origin: ChinaAfter-sales Service Provided: Engineers available to service machinery overseasCondition: NewApplication: Viscous FluidDongguan Xinbao Machinery Co., Ltd1 Yr

High Performance Stainless Steel Liquid Mixing BoilerNegotiableMOQ: 1 SetPlace of Origin: ChinaAfter-sales Service Provided: Engineers available to service machinery overseasCondition: NewApplication: Viscous FluidDongguan Xinbao Machinery Co., Ltd1 Yr Multifunctional Food Mixer, Stainless Steel Seasoning MixerUS$ 5500MOQ: 1 UnitType: MixerWarranty: One yearVoltage: 380VUsage: OtherHenan Panqi Heavy Industry Technology Co., Ltd.1 Yr

Multifunctional Food Mixer, Stainless Steel Seasoning MixerUS$ 5500MOQ: 1 UnitType: MixerWarranty: One yearVoltage: 380VUsage: OtherHenan Panqi Heavy Industry Technology Co., Ltd.1 Yr High-precision Carbon Steel Flange Customization Large Diameter Stainless Steel Flanging Butt Welding Flange Carbon Steel Flat Welding FlangeUS$ 1.5 - 100MOQ: 1 PieceBrand Name: no brandPlace of Origin: ChinaModel Number: DN15-DN1500Material: Stainless SteelJingjiang Fuji Technology Co., Ltd.4 Yrs

High-precision Carbon Steel Flange Customization Large Diameter Stainless Steel Flanging Butt Welding Flange Carbon Steel Flat Welding FlangeUS$ 1.5 - 100MOQ: 1 PieceBrand Name: no brandPlace of Origin: ChinaModel Number: DN15-DN1500Material: Stainless SteelJingjiang Fuji Technology Co., Ltd.4 Yrs High End Drill Bits Cobalt Containing Stainless Steel Twist Drill Bits Fully Ground Genuine High Speed SteelNegotiableMOQ: 50 PiecesMaterial: DiamondType: Other, Drill bit chiselUse: Metal DrillingYueqing Ruichen Electronic Co., LTD1 Yr

High End Drill Bits Cobalt Containing Stainless Steel Twist Drill Bits Fully Ground Genuine High Speed SteelNegotiableMOQ: 50 PiecesMaterial: DiamondType: Other, Drill bit chiselUse: Metal DrillingYueqing Ruichen Electronic Co., LTD1 Yr Durable Stainless Steel Laser Hair Removal Machine With Medical-Grade MaterialsUS$ 2000 - 3000MOQ: 1 UnitApplication: Other, Professional clinicsMaterial: Medical-grade stainless steelLaser Type: Diode laser systemSafety Features: Skin temperature monitoringBeijing Adamei Technology Development Co., Ltd.1 Yr

Durable Stainless Steel Laser Hair Removal Machine With Medical-Grade MaterialsUS$ 2000 - 3000MOQ: 1 UnitApplication: Other, Professional clinicsMaterial: Medical-grade stainless steelLaser Type: Diode laser systemSafety Features: Skin temperature monitoringBeijing Adamei Technology Development Co., Ltd.1 Yr SKF Stainless Steel Bearing Deep Groove Ball Bearings 7209BE-2RZPNegotiableMOQ: 10 PiecesBeijing SKF Bearing Trading Co., Ltd.1 Yr

SKF Stainless Steel Bearing Deep Groove Ball Bearings 7209BE-2RZPNegotiableMOQ: 10 PiecesBeijing SKF Bearing Trading Co., Ltd.1 Yr WRH-100B Middle Temperature Stainless Steel Fruit And Vegetable DehydratorNegotiableMOQ: 1 SetPlace of Origin: ChinaType: Flash Drying EquipmentAfter-sales Service Provided: Overseas third-party support availableCondition: NewXiAn Wisdom Computer Info&tech Co., Ltd8 Yrs

WRH-100B Middle Temperature Stainless Steel Fruit And Vegetable DehydratorNegotiableMOQ: 1 SetPlace of Origin: ChinaType: Flash Drying EquipmentAfter-sales Service Provided: Overseas third-party support availableCondition: NewXiAn Wisdom Computer Info&tech Co., Ltd8 Yrs Stainless Steel Food Packing Machine With Adjustable Size for Various Food ProductsNegotiableMOQ: 1 AcreApplication: Other, Food Products PackagingMaterial: Stainless SteelSize: Adjustable for various dimensionsCertifications: HACCP, SA8000Goldsupplier Tests Store4 Yrs

Stainless Steel Food Packing Machine With Adjustable Size for Various Food ProductsNegotiableMOQ: 1 AcreApplication: Other, Food Products PackagingMaterial: Stainless SteelSize: Adjustable for various dimensionsCertifications: HACCP, SA8000Goldsupplier Tests Store4 Yrs Henry Explosion-proof Safety Valve 5626 5627 5628 5629-150 250 300-CE Stainless SteelUS$ 300 - 8000MOQ: 1 PieceBrand Name: HenryPlace of Origin: ChinaModel Number: Henry explosion-proof safety valve 5626 5627 5628 5629-150 250 300-CE stainless steelCertification: CEDongguan Shun Chi Mechanical And Electrical Equipment Co. , Ltd.3 Yrs

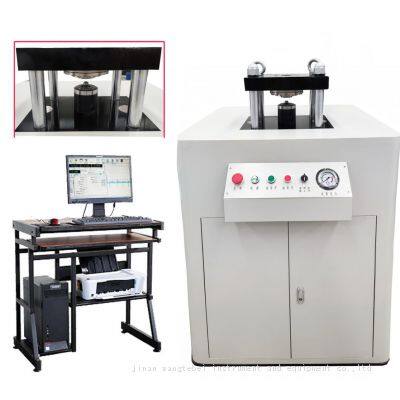

Henry Explosion-proof Safety Valve 5626 5627 5628 5629-150 250 300-CE Stainless SteelUS$ 300 - 8000MOQ: 1 PieceBrand Name: HenryPlace of Origin: ChinaModel Number: Henry explosion-proof safety valve 5626 5627 5628 5629-150 250 300-CE stainless steelCertification: CEDongguan Shun Chi Mechanical And Electrical Equipment Co. , Ltd.3 Yrs Earing Test in Packaging Industry Deep Drawing Quality Control Earing Test Earing Test for Stainless Steel SheetsUS$ 12000 - 17000MOQ: 1 SetType: Other, cupping testing machineWeight: 100-500KgPower Source: AC380VAccuracy Grade: 1Jinan Wangtebei Instrument And Equipment Co.,ltd1 Yr

Earing Test in Packaging Industry Deep Drawing Quality Control Earing Test Earing Test for Stainless Steel SheetsUS$ 12000 - 17000MOQ: 1 SetType: Other, cupping testing machineWeight: 100-500KgPower Source: AC380VAccuracy Grade: 1Jinan Wangtebei Instrument And Equipment Co.,ltd1 Yr CAT 295-3099 Caterpillar 2953099 Stainless Steel Spark Plug Engine C7 C9.3NegotiableMOQ: 1 PieceBrand Name: Stainless Steel Spark PlugModel Number: 295-3099 2953099Ningbo Qiuning Trading Co., Ltd3 Yrs

CAT 295-3099 Caterpillar 2953099 Stainless Steel Spark Plug Engine C7 C9.3NegotiableMOQ: 1 PieceBrand Name: Stainless Steel Spark PlugModel Number: 295-3099 2953099Ningbo Qiuning Trading Co., Ltd3 Yrs Factory Price Stainless Steel Hot Sauce Making Equipment Hot Sauce Making MachineNegotiableMOQ: 1 SetType: Other, chili sauce making machineAfter-sales Service: SupportCustomized: CustomizedTransport Package: Standard packagingHenan Gelgoog Machinery CO,LTD2 Yrs

Factory Price Stainless Steel Hot Sauce Making Equipment Hot Sauce Making MachineNegotiableMOQ: 1 SetType: Other, chili sauce making machineAfter-sales Service: SupportCustomized: CustomizedTransport Package: Standard packagingHenan Gelgoog Machinery CO,LTD2 Yrs Importer submitted an RFQ for Stainless Steel V-Type Ball Valve Featuring V-Shaped Notch for Fibrous and Granular Media Control25 minutes ago

Importer submitted an RFQ for Stainless Steel V-Type Ball Valve Featuring V-Shaped Notch for Fibrous and Granular Media Control25 minutes ago Importer inquired about Magnetic Flap Level Gauge with ±10mm Accuracy, Stainless Steel/PTFE Construction, High-Sealing for Leak-Proof in Harsh Industrial Conditions2025-11-12 19:30:37

Importer inquired about Magnetic Flap Level Gauge with ±10mm Accuracy, Stainless Steel/PTFE Construction, High-Sealing for Leak-Proof in Harsh Industrial Conditions2025-11-12 19:30:37 Procurement Lead verified certifications for Stainless Steel 316L Pressure Sensor with Heat Sink for Extreme Conditions in Petrochemical, Power & Food Processing Industries2025-11-15 22:31:58

Procurement Lead verified certifications for Stainless Steel 316L Pressure Sensor with Heat Sink for Extreme Conditions in Petrochemical, Power & Food Processing Industries2025-11-15 22:31:58 Lead Purchaser requested specs for mobile stainless steel tables2025-11-14 14:22:42

Lead Purchaser requested specs for mobile stainless steel tables2025-11-14 14:22:42 Importer requested a quote for Stainless steel sink(clean room sink & clean room equipment)2025-11-14 10:38:12

Importer requested a quote for Stainless steel sink(clean room sink & clean room equipment)2025-11-14 10:38:12 Business Owner placed an order for Stainless steel single-sided exhaust hood2025-11-15 16:38:40

Business Owner placed an order for Stainless steel single-sided exhaust hood2025-11-15 16:38:40 Import Coordinator requested specs for Industrial F111 Hot-Insertion Flow Sensor | Stainless Steel/Brass Body, Battery-Powered Option, Compatible with Data Loggers2025-11-12 20:59:19

Import Coordinator requested specs for Industrial F111 Hot-Insertion Flow Sensor | Stainless Steel/Brass Body, Battery-Powered Option, Compatible with Data Loggers2025-11-12 20:59:19 Procurement Lead verified certifications for Split type silicon piezoresistive liquid level transmitter for Water Treatment, Heavy Oil, stainless steel level transmitter2025-11-15 13:50:24

Procurement Lead verified certifications for Split type silicon piezoresistive liquid level transmitter for Water Treatment, Heavy Oil, stainless steel level transmitter2025-11-15 13:50:24 Buyer is sourcing stainless steel working table2025-11-13 05:01:36

Buyer is sourcing stainless steel working table2025-11-13 05:01:36 Sourcing Agent negotiating terms for stainless steel restaurant working tables2025-11-14 16:26:31

Sourcing Agent negotiating terms for stainless steel restaurant working tables2025-11-14 16:26:31 High Precision Oem CNC Machining Service Custom Stainless Steel Alloys Aluminum Brass Bronze Copper Cnc Milling Turning PartsUS$ 12MOQ: 10 UnitsMaterial: Nylon, Steel, Plastic, Brass, Alloy, Copper, Aluminum, Iron, OtherApplication: Fastener, Auto and Motorcycle Accessory, Hardware Tool, Machinery Accessory, OtherStandard: GB, EN, API650, China GB Code, JIS Code, TEMA, ASME, OtherProduction Type: Mass ProductionNingbo Changfeng Mechanical Factory1 Yr

High Precision Oem CNC Machining Service Custom Stainless Steel Alloys Aluminum Brass Bronze Copper Cnc Milling Turning PartsUS$ 12MOQ: 10 UnitsMaterial: Nylon, Steel, Plastic, Brass, Alloy, Copper, Aluminum, Iron, OtherApplication: Fastener, Auto and Motorcycle Accessory, Hardware Tool, Machinery Accessory, OtherStandard: GB, EN, API650, China GB Code, JIS Code, TEMA, ASME, OtherProduction Type: Mass ProductionNingbo Changfeng Mechanical Factory1 Yr Frank Stainless Steel HouseUS$ 10 - 120MOQ: 1 SetPlace of Origin: Shanghai, ChinaBrand Name: sinoarchModel Number: TE--0098Material: Other, Steel, SteelSinoarch Shanghai Co., Ltd.5 Yrs

Frank Stainless Steel HouseUS$ 10 - 120MOQ: 1 SetPlace of Origin: Shanghai, ChinaBrand Name: sinoarchModel Number: TE--0098Material: Other, Steel, SteelSinoarch Shanghai Co., Ltd.5 Yrs Industrial Stainless Steel HouseUS$ 10 - 120MOQ: 1 SetPlace of Origin: Shanghai, ChinaBrand Name: sinoarchModel Number: TE--0098Material: Other, Steel, SteelSinoarch Shanghai Co., Ltd.5 Yrs

Industrial Stainless Steel HouseUS$ 10 - 120MOQ: 1 SetPlace of Origin: Shanghai, ChinaBrand Name: sinoarchModel Number: TE--0098Material: Other, Steel, SteelSinoarch Shanghai Co., Ltd.5 Yrs Single Stainless Steel HouseUS$ 10 - 120MOQ: 1 SetPlace of Origin: Shanghai, ChinaBrand Name: sinoarchModel Number: TE--0098Material: Other, Steel, SteelSinoarch Shanghai Co., Ltd.5 Yrs

Single Stainless Steel HouseUS$ 10 - 120MOQ: 1 SetPlace of Origin: Shanghai, ChinaBrand Name: sinoarchModel Number: TE--0098Material: Other, Steel, SteelSinoarch Shanghai Co., Ltd.5 Yrs Stainless Steel TableUS$ 50 - 250MOQ: 1 SetMaterial: Other, Metal, Glass,Aluminium,CeramicMetal Type: Stainless SteelAppearance: AntiqueFolded: NoSinoarch Shanghai Co., Ltd.5 Yrs

Stainless Steel TableUS$ 50 - 250MOQ: 1 SetMaterial: Other, Metal, Glass,Aluminium,CeramicMetal Type: Stainless SteelAppearance: AntiqueFolded: NoSinoarch Shanghai Co., Ltd.5 Yrs Folding Stainless Steel TableUS$ 50 - 250MOQ: 1 SetMaterial: Other, Metal, Glass,Aluminium,CeramicMetal Type: Stainless SteelAppearance: AntiqueFolded: YesSinoarch Shanghai Co., Ltd.5 Yrs

Folding Stainless Steel TableUS$ 50 - 250MOQ: 1 SetMaterial: Other, Metal, Glass,Aluminium,CeramicMetal Type: Stainless SteelAppearance: AntiqueFolded: YesSinoarch Shanghai Co., Ltd.5 Yrs