Screw Barrel Insights & Buyer's Guide

The screw barrel has met the final counterpart in extrusion technology, reshaping how materials are processed on the industrial front. Moving from the production of highly complicated items into plastics to more recent technology for the advancement of sustainable material, it is screw barrel design that has brought efficiency, accuracy, and flexibility into the modern day process. Herein, we discuss the recent progress in screw barrel technology, various industrial applications, and the impact of these developments on productivity and product quality. So, for manufacturers, engineers, and curious people who want to know how extrusion systems are made, this guide offers valuable information on how this critical component is shaping industrial production for the future.

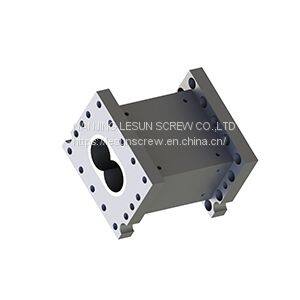

Understanding the Screw Barrel

Definition and Components of Screw and Barrel

It is an indispensable element in extrusion and injection molding systems: this machine can melt, mix, and convey into compress. The screw, often made of high strength alloys, travels with the barrel in controlling temperature and pressure to ensure the flow of material at a substrate rate in itself. Bimetallic construction of the barrel and newer screw designs is a step towards making the barrel more durable, ensuring minimum wear, increased energy absorption, and allowing for smoother working methods. These developments confront the real challenges the industry faces in terms of inactivity and higher output quality, making screw barrel genuinely indispensable in modern processes.

Types of Screw Barrels Used in Extruders

Standard Screw Barrels

These are the most commonly used barrels designed for general-purpose extrusion. They are typically made of nitrided steel or bimetallic materials, providing durability and resistance to wear and corrosion. Standard screw barrels are ideal for processing basic polymers and standard production needs.

Vented Screw Barrels

Featuring vents or openings along their length, vented screw barrels allow gases, moisture, or volatiles to escape during the extrusion process. This makes them highly suitable for materials that release significant amounts of gas or moisture, such as recycled plastics. The venting improves product quality and ensures smoother processing.

Twin Screw Barrels

Available in parallel or conical configurations, twin screw barrels are specifically designed to handle advanced material mixing and extrusion requirements. They are commonly used in applications requiring uniform material blending, such as compounding and producing high-performance polymers.

Grooved Feed Screw Barrels

Incorporating grooves in the feed section, these barrels enhance material grip and improve the feeding process. The grooves reduce the risk of material slippage, ensuring consistent production performance. They are typically utilized for high-output applications and challenging materials.

Barrier Screw Barrels

Barrier screw barrels include a barrier flight design that separates melted and unmelted material during extrusion. This ensures efficient melting and mixing of polymers, reducing defects and improving extrusion quality. They are especially beneficial for high-speed operations and materials requiring precise temperature control.

Each type of screw barrel is designed to address specific manufacturing challenges, offering tailored solutions to improve production efficiency, enhance product quality, and minimize downtime.

Working Principle of the Extruder Screw Barrel

The working principle of the extruder screw barrel involves a complex arrangement of mechanical movements and thermal dynamics; accordingly, it is considered fundamental in the realization of plastic materials into finished products. As rotation occurs between the barrel and the screw, plastic pellets are dropped down the feed hopper on entering the feed section of the screw. The material is first conveyed slowly along with slight compression and melting. The screw flights of the extruder help advance the material and exert pressure on it, thereby assisting in its melting. From here on, the plastic moves to the compression zone, gets completely molten, and gets thoroughly mixed and homogenized under strictly controlled temperature and pressure within the barrel to prevent overheating and ensure the free flow of molten plastic. Then, in the metering zone, under controlled pressure, the plastic mixture is finally extruded through the die into the desired shape. In this manner, good screw manufacturing and perfect choice of materials and designing become prerequisite requirements for fulfilling these objectives in plastic extrusion and injection molding.

Applications of Screw Barrels in Various Industries

Plastic Extrusion: Main Processes and Methods

Within the plastic realm, acknowledging the intense extrusion of screw barrels is extremely crucial. Plastic extrusion is, in a sense, a high-volume production process of extruding pellets of different types of thermoplastic resins, melting them with heat, and forming them into a continuous profile. This step constitutes the whole extrusion process and is where the screw barrel, more specifically the extruder screw, really begins to metamorphose the plastic pellets into molten plastic. This screw turns in the barrel. Accordingly, the design of the screw, comprising of different screw flights, including an intensification zone or sometimes a gradual decrease in the flight depth along the barrel, melts the materials that pass through and aids in mixing. An extrusion screw is adequate only when the compression ratio and flow dynamics of the screw chamber fit the type of resin being processed and the end product being produced. Moreover, when the process requires a more sophisticated set of parameters for temperature and pressure control inside the barrel, such as in twin screw extrusion, this process control is only enhanced, with resultant high-quality products demanded by the plastics industry. Throughout the years, a modular-type screw element introduction in extruder screws and barrels has given a new direction to manufacturers to quickly develop and customize the actual processes according to the needs of a fast-changing market.

Injection Molding: The Feeding Screw

A screw barrel is a crucial interfacing element for the transformation of plastics into complex shapes and forms in injection molding. Within the injection molding machine nest, the feed screw conveys and melts the plastic and causes the plastic to become homogenized before injection into the mold. Whereat materials are conveyed in numerous barrel zones, namely the feed zone and compression zone, increasing temperature and pressure gradually: and are affected greatly by consider the diameter of the screw, the length of various sections of the screw, and the design of screw flights, which have a direct bearing upon the quality of the molten plastic and efficiency of the molding process. The choice of the right feed screw is essential in attaining the desired results in injection molding because it impacts cycle time, energy consumption, and consistency of the products. Feed screws and barrels, which have been designed with higher wear resistance by such techniques as nitriding, also have improvements in strength and wear resistance of the feed screws and barrels. Consequently, injection molding will keep the need of industries for plastic parts of high precision being answered.

Manufacturing Applications: Beyond Plastics

Though screw barrels have become synonymous with plastics processing, the fact remains that the uses of screw barrels are beyond the scope of the plastics industry. Different manufacturing areas such as food, pharmaceutical drugs, and chemical plants use screw barrels for extrusion and molding of materials. Design changes of the screw and barrel may be of usage for different material masses and/or processing conditions, rendering them indispensable for a variety of industrial processes. For instance, the food industry uses screw barrels to extrude dough and other ingredients into particular shapes that require very precise control over temperature and pressure. In the same way, the pharmaceutical industry depends heavily on extrusion processes carried out via screw barrels to manufacture tablets and capsules that are uniform and of high quality. Customizing the compression ratio and various screw elements by relating them to specific material properties is key in these applications to ensure that they operate efficiently and reliably. Because screw manufacturing technology is continuously evolving through new designs with twin and single screw configurations, this opens wider prospects for the application of screw barrels for performance efficiency in a number of manufacturing areas.

Performance and Efficiency of Screw Barrels

Factors Affecting Performance in Extrusion Processes

Manufacturing efficiency can be maximized through screw barrel design, such that the highest manufacturing efficiency is demanded in the plastics and polymers manufacturing industries. Much attention has been given to advanced screws that enhance the flow of materials and reduce power consumption and wear. Some factors affecting throughput enhancement without reducing the level of product quality include screw geometry, compression ratio, surface coating, etc. Barrier screws, for instance, are being used more commonly because they separate and melt raw materials uniformly, thereby contributing to reduced processing time and improved consistency. Thus, a design of an efficient screw barrel translates into lowered production operational time and costs associated with it, occasioning competitive advantages in a high-demand sector.

Maintenance for Increasing Efficiency of Barrel Screw

Proper maintenance enhances the efficiency of screw barrels and increases their availability time. Regular inspection of the screw and barrel wear and damages can prevent possible damages to them and keep their performance at the optimum level. Cleaning of the barrel and screw to eliminate deposits and residues will prevent contamination of materials and ensure smooth operation. Lubricating of the screw and barrel surfaces will reduce friction and such friction aggravates wearing, thus leading to higher efficiency of the extrusion process. It is also advisable to monitor the screw diameter and compression ratio as these may provide indicators of wearor damage and require attention for adjustment or replacement. Implementation of a timely maintenance schedule to check alignment impurities and temperature, and pressure settings to ensure they are set appropriately, will avoid overheating and other common faults. If all maintenance activities are thoroughly performed, they shall serve to increase the efficiency of the screw barrels, thereby maintaining consistent quality in plastic processing and drastically reducing downtime in extrusion and injection molding operations.

The Issues of Wear and Tear: Challenges and Solutions

Wear and tear are general challenges faced by screw barrels in extrusion and injection molding, often compounded by the harsh environments under which these processes are carried out. The continuous rotation of the screw inside the barrel subjects the components to heavy mechanical stresses and friction that ultimately lead to gradual deterioration. To address this challenge, selecting the right materials for screw manufacturing is vital. For example, utilization of wear-resistant materials such as nitriding can provide superior wear resistance to feed screws and barrels. Regular inspection of the screw flights and screw diameter is a guarantee to discover instances of wear as early as possible, thus allowing for intervention as soon as possible. The use of modular screw elements can be a cheaper alternative that allows the replacement of worn sections without the need to replace the entire barrel and screw. Additionally, ensuring that the temperature and pressure settings are well maintained will help prevent excessive wear, as it would otherwise augment the friction and mechanical stress. By understanding these common challenges and implementing solutions that effectively enhance the longevity and efficiency of the screw barrels, manufacturers will boost their extrusion and molding performance.

Frequently Asked Questions (FAQs)

What is a screw barrel used for in plastic extrusion?

A screw barrel is an essential component in the plastic extrusion process, where it plays a crucial role in plasticizing and homogenizing the material. As the screw rotates within the barrel, it helps in evenly distributing the heat and pressure necessary to melt the plastic. This allows for a consistent performance when extruding various types of plastics. The design and length-to-diameter ratio of the screw barrel can significantly affect the output and the quality of the extruded product. Typically, a proper selection of materials and coatings, such as wear-resistant coatings, can enhance the service life of the screw barrel.

How does an extruder screw work?

The extruder screw functions by rotating along the extruder barrel, pushing the material through different zones where it is heated and melted. The rotating screw increases the pressure and promotes plasticization, allowing for effective processing of a range of materials. During this process, trapped air can be removed, leading to better material uniformity. Different designs of screws can be used depending on the specific processing needs, such as those for handling abrasive materials like calcium carbonate or talc. This versatility makes extruder screws vital in molding industries for both injection molding and extrusion molding.

What are the benefits of using OEM screw and barrel combinations?

Using OEM screw and barrel combinations ensures compatibility and optimal performance tailored to specific machinery and applications. These combinations are typically designed to meet the unique requirements of the extrusion process, allowing for increased output and improved efficiency. OEM parts often feature advanced designs that enhance plasticization and minimize wear, extending the service life of the components. Additionally, they can be engineered with specific materials, such as steel alloys or specialized coatings, to withstand harsh processing conditions. Investing in OEM solutions can lead to better homogenization and a reduction in maintenance costs over time.

What repair services are available for screw barrels?

Repair services for screw barrels typically include reconditioning, resurfacing, and replacing worn-out components. These services are crucial for extending the life and functionality of existing equipment, especially when dealing with wear-resistant coatings that may deteriorate over time. Technicians can often restore the screw and barrel to their original specifications, improving performance and efficiency. Regular maintenance and prompt repairs can prevent costly downtime in production, ensuring that the extrusion process remains consistent. In some cases, upgrading to newer designs during repairs can also enhance output and reduce material waste.

Can different types of screws be used in the same barrel?

Using different types of screws in the same barrel is generally not recommended due to variations in design and functionality. Each screw is engineered to work with specific materials and processing parameters, and mismatching can lead to inefficiencies or damage. For example, a feed screw designed for a specific plastic type may not perform well if paired with an extruder screw meant for a different application. However, in some cases, a hybrid approach using specialized screws can be beneficial, provided they are compatible. It's essential to consult with experts to determine the best combinations for specific processing needs.

Polycarbonate Moulding Machine Low Noise Dual Alloy 39crmoal Screw And BarrelUS$ 15,000 - 45,000MOQ: 1 SetAfter-sales Service Provided: Engineers available to service machinery overseasWarranty: 3XiAn Wisdom Computer Info&tech Co., Ltd8 Yrs

Polycarbonate Moulding Machine Low Noise Dual Alloy 39crmoal Screw And BarrelUS$ 15,000 - 45,000MOQ: 1 SetAfter-sales Service Provided: Engineers available to service machinery overseasWarranty: 3XiAn Wisdom Computer Info&tech Co., Ltd8 Yrs Plastic Flat Head Barrel Furniture Screw Plastic End Cap CoverNegotiableMOQ: 100 PiecesBrand Name: MOCAPPlace of Origin: ChinaModel Number: BPF30Plastic Modling Type: InjectionZhongshan MOCAP Industry Co.,LTD1 Yr

Plastic Flat Head Barrel Furniture Screw Plastic End Cap CoverNegotiableMOQ: 100 PiecesBrand Name: MOCAPPlace of Origin: ChinaModel Number: BPF30Plastic Modling Type: InjectionZhongshan MOCAP Industry Co.,LTD1 Yr JHH-2000 Mixing Screw BarrelUS$ 2,000 - 275,000MOQ: 1 SetCondition: NewMixer Type: RibbonProduct Type: FertilizerApplication: PowderZhengzhou Jinhe Machinery Manufacture Co., Ltd.5 Yrs

JHH-2000 Mixing Screw BarrelUS$ 2,000 - 275,000MOQ: 1 SetCondition: NewMixer Type: RibbonProduct Type: FertilizerApplication: PowderZhengzhou Jinhe Machinery Manufacture Co., Ltd.5 Yrs Styrofoam Forming Machine Screw BarrelUS$ 1 - 31,000MOQ: 1 SetCondition: NewPlace of Origin: Shandong, ChinaBrand Name: TYModel Number: PSZ-900Longkou Unity Machinery Equipment Co., Ltd.5 Yrs

Styrofoam Forming Machine Screw BarrelUS$ 1 - 31,000MOQ: 1 SetCondition: NewPlace of Origin: Shandong, ChinaBrand Name: TYModel Number: PSZ-900Longkou Unity Machinery Equipment Co., Ltd.5 Yrs Alloy 38CrMoAL/38CrMoAlA Steel Bar for Screw BarrelUS$ 2,150 - 2,150MOQ: 2000 KilogramsBrand Name: CunRuiPlace of Origin: Jiangsu, ChinaModel Number: Incoloy 800 800H 825 925Type: Nickel BarJiangsu Cunrui Metal Products Co., Ltd.5 Yrs

Alloy 38CrMoAL/38CrMoAlA Steel Bar for Screw BarrelUS$ 2,150 - 2,150MOQ: 2000 KilogramsBrand Name: CunRuiPlace of Origin: Jiangsu, ChinaModel Number: Incoloy 800 800H 825 925Type: Nickel BarJiangsu Cunrui Metal Products Co., Ltd.5 Yrs Feiyide Zinc Nickel Screws Barrel Plating MachineUS$ 800 - 2,000MOQ: 1 PiecePlace of Origin: Guangdong, ChinaBrand Name: FeiyideModel Number: FYD-TDongguan Feiyide Automation Equipment Co., Ltd.5 Yrs

Feiyide Zinc Nickel Screws Barrel Plating MachineUS$ 800 - 2,000MOQ: 1 PiecePlace of Origin: Guangdong, ChinaBrand Name: FeiyideModel Number: FYD-TDongguan Feiyide Automation Equipment Co., Ltd.5 Yrs Barrel Nut and ScrewUS$ 0.001 - 0.01MOQ: 50000 PiecesPlace of Origin: Jiangsu, ChinaBrand Name: insert nut screwModel Number: insert nut screwStandard: Other, insert nut screw, DIN, ISO, JIS, AISISuzhou Runtai Precision Hardware Co., Ltd.5 Yrs

Barrel Nut and ScrewUS$ 0.001 - 0.01MOQ: 50000 PiecesPlace of Origin: Jiangsu, ChinaBrand Name: insert nut screwModel Number: insert nut screwStandard: Other, insert nut screw, DIN, ISO, JIS, AISISuzhou Runtai Precision Hardware Co., Ltd.5 Yrs Advertisement Nails Barrel Screws Glass Standoff Pins/ Wall Mount Standoff Nail for Glass Quality ChoiceUS$ 0.2 - 0.8MOQ: 1000 PiecesPlace of Origin: Guangdong, ChinaBrand Name: BeautifulModel Number: BDF-0058 Glass Standoff;Material: AcrylicGuangzhou Beautiful Hardware Manufacture Ltd.5 Yrs

Advertisement Nails Barrel Screws Glass Standoff Pins/ Wall Mount Standoff Nail for Glass Quality ChoiceUS$ 0.2 - 0.8MOQ: 1000 PiecesPlace of Origin: Guangdong, ChinaBrand Name: BeautifulModel Number: BDF-0058 Glass Standoff;Material: AcrylicGuangzhou Beautiful Hardware Manufacture Ltd.5 Yrs SEGMENT SCREW & BARRELUS$ 100 - 1000MOQ: 1 SetBrand Name: Ningbo Tizatech Machinery Technology Company Ltd.,Place of Origin: ChinaModel Number: SEGMENT SCREW & BARRELNingbo Tianze Machinery Technology Co.,

SEGMENT SCREW & BARRELUS$ 100 - 1000MOQ: 1 SetBrand Name: Ningbo Tizatech Machinery Technology Company Ltd.,Place of Origin: ChinaModel Number: SEGMENT SCREW & BARRELNingbo Tianze Machinery Technology Co., Screw Barrel for Extrusion Machines and Injection Molding MachinesNegotiableMOQ: 1 PiecePlace of Origin: ChinaModel Number: 55/110, 65/132, 80/156, 92/188 conical screw barrel, 90 twin, 71 twinE.j.s Industry Co., Ltd

Screw Barrel for Extrusion Machines and Injection Molding MachinesNegotiableMOQ: 1 PiecePlace of Origin: ChinaModel Number: 55/110, 65/132, 80/156, 92/188 conical screw barrel, 90 twin, 71 twinE.j.s Industry Co., Ltd High Quality Extrusion Screw and Barrel for Engel Injection Machine ExtruderUS$ 899 - 1118MOQ: 1 PieceBrand Name: JGHPlace of Origin: ChinaModel Number: JGH-001Certification: ISO 9001Guangdong Juguangheng Automation Equipment Co., Ltd.

High Quality Extrusion Screw and Barrel for Engel Injection Machine ExtruderUS$ 899 - 1118MOQ: 1 PieceBrand Name: JGHPlace of Origin: ChinaModel Number: JGH-001Certification: ISO 9001Guangdong Juguangheng Automation Equipment Co., Ltd. Screw BarrelNegotiableMOQ: 1 SetBrand Name: shenglong screwPlace of Origin: ChinaModel Number: 1Zhoushan Shenglong Machinery Co., Ltd

Screw BarrelNegotiableMOQ: 1 SetBrand Name: shenglong screwPlace of Origin: ChinaModel Number: 1Zhoushan Shenglong Machinery Co., Ltd Screw BarrelNegotiableMOQ: 1 SetBrand Name: lichaoPlace of Origin: ChinaZhoushan Lichao Plastic Mahinery Co.,Ltd

Screw BarrelNegotiableMOQ: 1 SetBrand Name: lichaoPlace of Origin: ChinaZhoushan Lichao Plastic Mahinery Co.,Ltd Screw&barrelNegotiableMOQ: 1 SetPlace of Origin: ChinaNingbo Haiying Plastics Machinery Co., Ltd.

Screw&barrelNegotiableMOQ: 1 SetPlace of Origin: ChinaNingbo Haiying Plastics Machinery Co., Ltd. Screws BarrelsUS$ 100 - 500MOQ: 1 SetBrand Name: AnupamModel Number: AnupamAnupam Heaters And Controls Private Limited

Screws BarrelsUS$ 100 - 500MOQ: 1 SetBrand Name: AnupamModel Number: AnupamAnupam Heaters And Controls Private Limited Screw Barrel Tip, Screw Barrel,bimetallic Screw BarrelNegotiableMOQ: 1 PieceBrand Name: Jinyi screwPlace of Origin: ChinaModel Number: Jy-fj003Ningbo Jinyi Mechanical & Electrical Co.,Ltd.

Screw Barrel Tip, Screw Barrel,bimetallic Screw BarrelNegotiableMOQ: 1 PieceBrand Name: Jinyi screwPlace of Origin: ChinaModel Number: Jy-fj003Ningbo Jinyi Mechanical & Electrical Co.,Ltd. SKD16 Screw Barrel/Parallel Screw Barrel/Extruder Screw BarrelUS$ 150 - 150MOQ: 1 PiecePlace of Origin: ChinaNingbo Cowell Industry Co,Ltd

SKD16 Screw Barrel/Parallel Screw Barrel/Extruder Screw BarrelUS$ 150 - 150MOQ: 1 PiecePlace of Origin: ChinaNingbo Cowell Industry Co,Ltd Extrusion Screw Barrel, Extruder Screw Barrels, Screw Barrel for Plastic MachineryUS$ 50 - 50MOQ: 1 PieceBrand Name: Tywei ScrewPlace of Origin: ChinaModel Number: TW-Extrusion screw barrel005Ningbo Tywei Precision Machinery Co.,Ltd.

Extrusion Screw Barrel, Extruder Screw Barrels, Screw Barrel for Plastic MachineryUS$ 50 - 50MOQ: 1 PieceBrand Name: Tywei ScrewPlace of Origin: ChinaModel Number: TW-Extrusion screw barrel005Ningbo Tywei Precision Machinery Co.,Ltd. Feeding Screw Barrel Extruder Screw Barrel Rubber Machine Screw BarrelUS$ 50 - 500MOQ: 1 PieceCondition: NewApplication: FilmPlastic Processed: PEScrew Design: Single-screwZhejiang Zhongyang Screw Manufacturing Co., Ltd.

Feeding Screw Barrel Extruder Screw Barrel Rubber Machine Screw BarrelUS$ 50 - 500MOQ: 1 PieceCondition: NewApplication: FilmPlastic Processed: PEScrew Design: Single-screwZhejiang Zhongyang Screw Manufacturing Co., Ltd. Screw Barrel/ Rubber Screw Barrel/rubber Screw Barrel ManufacturerUS$ 100 - 18,000MOQ: 1 SetPlace of Origin: Zhejiang, ChinaBrand Name: ZhongSuModel Number: ZS15-360mmZhejiang Zhongsu Screw Co., Ltd.

Screw Barrel/ Rubber Screw Barrel/rubber Screw Barrel ManufacturerUS$ 100 - 18,000MOQ: 1 SetPlace of Origin: Zhejiang, ChinaBrand Name: ZhongSuModel Number: ZS15-360mmZhejiang Zhongsu Screw Co., Ltd. Purchasing Director requested specs for bimetallic extrusion screw barrel2025-11-16 11:19:40

Purchasing Director requested specs for bimetallic extrusion screw barrel2025-11-16 11:19:40 Purchasing Director requested specs for Single screw barrel, Screw barrel for injection molding machine2025-11-15 05:09:10

Purchasing Director requested specs for Single screw barrel, Screw barrel for injection molding machine2025-11-15 05:09:10 Import Coordinator verified certifications for tungsten carbide screw barrel2025-11-16 09:38:04

Import Coordinator verified certifications for tungsten carbide screw barrel2025-11-16 09:38:04 Procurement Lead negotiating terms for Assemblie Parts Of Screw & Barrel23 hours ago

Procurement Lead negotiating terms for Assemblie Parts Of Screw & Barrel23 hours ago Importer requested specs for screw barrel with high quality10 hours ago

Importer requested specs for screw barrel with high quality10 hours ago Nitriding Technology Screw Barrel and Screw Barrel for ExtruderUS$ 80 - 10,000MOQ: 1 PiecePlace of Origin: Zhejiang, ChinaBrand Name: EJSModel Number: conical twin screw barrelNingbo E.J.S Plastic Machinery Co., Ltd.

Nitriding Technology Screw Barrel and Screw Barrel for ExtruderUS$ 80 - 10,000MOQ: 1 PiecePlace of Origin: Zhejiang, ChinaBrand Name: EJSModel Number: conical twin screw barrelNingbo E.J.S Plastic Machinery Co., Ltd. Bimetallic Injection Screw Barrel Extruder Screws BarrelsUS$ 1 - 10,000MOQ: 1 SetPlace of Origin: Zhejiang, ChinaBrand Name: QY screw barrelModel Number: 110Zhoushan Qunying Plastic Machinery Manufactory

Bimetallic Injection Screw Barrel Extruder Screws BarrelsUS$ 1 - 10,000MOQ: 1 SetPlace of Origin: Zhejiang, ChinaBrand Name: QY screw barrelModel Number: 110Zhoushan Qunying Plastic Machinery Manufactory Screw Barrel for Injection Molding Screw BarrelUS$ 500 - 100,000MOQ: 1 SetPlace of Origin: Zhejiang, ChinaBrand Name: shenglongModel Number: screw barrelZhoushan Shenglong Machinery Co., Ltd.

Screw Barrel for Injection Molding Screw BarrelUS$ 500 - 100,000MOQ: 1 SetPlace of Origin: Zhejiang, ChinaBrand Name: shenglongModel Number: screw barrelZhoushan Shenglong Machinery Co., Ltd. Bimetallic Barrel, Screw BarrelNegotiableMOQ: 1 SetBrand Name: LichaoPlace of Origin: ChinaNingbo Zhenhai Jinyi Mechanical And Electrical Co.,Ltd

Bimetallic Barrel, Screw BarrelNegotiableMOQ: 1 SetBrand Name: LichaoPlace of Origin: ChinaNingbo Zhenhai Jinyi Mechanical And Electrical Co.,Ltd Conical Twin Screw BarrelUS$ 0.0001 - 5MOQ: 300 KilogramsPlace of Origin: Zhejiang, ChinaStandard: DINNingbo Sardis Hardware Co., Ltd.

Conical Twin Screw BarrelUS$ 0.0001 - 5MOQ: 300 KilogramsPlace of Origin: Zhejiang, ChinaStandard: DINNingbo Sardis Hardware Co., Ltd. Extruder Twin Screw BarrelUS$ 16,000 - 888,888,888MOQ: 1 SetCondition: NewApplication: PlatesPlastic Processed: PVCScrew Design: Double-screwQingdao Hanhai Plastic Machinery Co., Ltd.

Extruder Twin Screw BarrelUS$ 16,000 - 888,888,888MOQ: 1 SetCondition: NewApplication: PlatesPlastic Processed: PVCScrew Design: Double-screwQingdao Hanhai Plastic Machinery Co., Ltd. Bimetallic Injection Screw BarrelUS$ 50 - 600MOQ: 10 SetsPlace of Origin: Zhejiang, ChinaBrand Name: BattenModel Number: HaitianZhoushan Batten Machinery Technology Co., Ltd.

Bimetallic Injection Screw BarrelUS$ 50 - 600MOQ: 10 SetsPlace of Origin: Zhejiang, ChinaBrand Name: BattenModel Number: HaitianZhoushan Batten Machinery Technology Co., Ltd.