Engine Part Insights & Buyer's Guide

An engine is the most essential aspect of any automobile, as it takes chemical energy and converts it into motion energy that eventually moves the car. This guide strives to unpack the working of each engine part as a unit and together as a system. It is vital to know the basic structure and functioning of an automotive or diesel engine, including its principal components and parts, regardless of one’s experience levels in their field, and for maintenance purposes as well. In order to advance the appreciation of the mechanisms that enable the use of engines, it is necessary to understand what the individual parts of the engine are and how they work.

Basics of Engine Parts

Overview of Basic Parts of a Car Engine

Automobiles are complex machines that consist of interacting systems, each containing numerous engine parts. Those parts include the following:

The cylinder and the cylinder head, because it is in these parts where compression is created with the piston in order to burn the mixture of air and fuel.

The camshaft and the crankshaft are the moving parts that allow the engine’s valves to be opened at the right moment.

The gasoline engines, on the other hand, use a spark plug that ignites the gas when it is compressed, whereas the diesel engines use only compression. In addition, among the important parts is the intake manifold, which facilitates the flow of air into the cylinders, and the exhaust system, which aids in exhausting burnt gases out. The oil filler tube, as well as the engine oil, ensures the lubrication of the moving parts and the smooth and proper operation of the engine.

Key Components of Diesel Engines

Diesel engines are efficient and long-lasting. Many features of the diesel engine are the same as in a gasoline engine, although only the mode of operation is different. Within these engines, rather than a spark plug, the fuel mixture is introduced into the cylinder under extremely high pressure and gets ignited due to compression. The cylinder block is the engine part that makes it possible for reach values to be achieved. The crankshaft is critical because it is used to turn these linear dimensional motions into rotations. Diesel engines also have very strong injection systems that precisely deliver fuel to the combustion chamber. Exhaust and intake valves are required to control gases; some other parts, such as the water pump or the crankcase heater, and engine oil, help to cool and lubricate the components, respectively. This structure helps in the maintenance of diesel engines, which are popular for how long they last and how strong they are.

How Different Engine Parts Work Together

The engine parts systems synergize and work together as one to enable effective operation of the internal combustion engine. The piston travels down the cylinder after compressing the air/fuel mixture, and the process of combustion begins, which is ultimately initiated by a spark plug or compression-based ignition. The piston is then pushed further down by the combustion force, which turns the crankshaft to generate energy. This can be achieved through the rotation of the camshaft, which is timed by the crankshaft with the help of a timing chain so as to control the above-mentioned intake and exhaust valve actuation. The oil in the engines helps in the lubrication of the bearing and any moving parts of the engine, and the lifter and the rocker arms hold the valve in place with precision. Together, this set works as an integrated mechanism to drive the car, emphasizing each of the parts and their place in the engine as a whole.

Cylinder and Dynamics of Cylinder Head

Role of the Cylinder in Vehicle Efficiency

The cylinder, often referred to as the engine part within an Internal Combustion Engine, is the cavity where the essential engine operations of combustion take place. Within a cylinder, a piston reciprocates up and down, compressing the air-fuel mix in preparation for the discharge of the spark. The efficacy of the cylinder is detrimental in the sense that it affects the engine power and fuel consumption of the car. The cylinder needs to function properly because, if not, it leads to loss of compression, which in turn translates to less energy recovery. Additionally, the structure and state of the cylinder are important for easing the motion of the piston and consequently optimizing and prolonging the performance of the engine.

Design of Cylinder Head and Its Significance

The cylinder head is seated on top of the cylinder block and completes the combustion cylinder’s seal. It is a crucial engine part as it houses the essential elements such as the inlet and outlet valves, the spark plugs, and in some types, the camshafts. The cylinder head design is significant as it aids in the improvement of the engine while performing gas exchange processes. Such designs have ambitious geometrical shapes for a perfect approximation to the combustion shape that promotes in-combustion and after-combustion exhaust. Moreover, the cylinder head has to take the loads acting on it, such as the pressures and the temperature of the combustion process; therefore, the materials have to be strong and with a high heat transfer capacity. In this respect, the consideration of the cylinder head assures the conservation of the engine's strength and efficiency.

Why Cylinder Head Care is Necessary

In vital engines, proper care of the cylinder head is critical for the effective and efficient performance of the engine over a long period of time. As such, most of the common problems, such as leakages, warping, and cracks, all of which can result in heavy loss of engine performance or engine failure, are mitigated through regular inspections and maintenance. This would entail not only checking whether the head gasket is intact, but also confirming the seating of the valves and action of the spark plugs and other elements. Last but not least, a clean cylinder head that is free of carbon buildup is useful in ensuring proper ventilation as well as combustion. Routine maintenance increases fuel economy and increases the durability of the engine; hence, it is indispensable in good management of not only car engines but also diesel engines.

Critical Engine Components

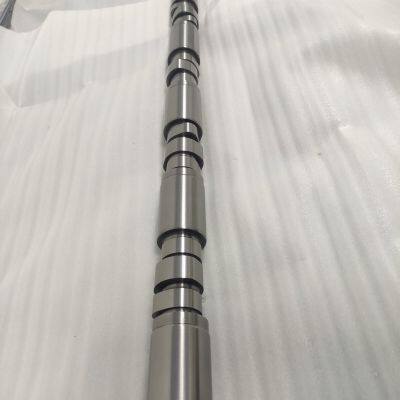

Exploring the Camshaft and Its Role

The camshaft is an essential engine part used within an engine for its effective valve timing. In a piston-driven internal combustion engine, the camshaft is contained within the cylinder head in the same manner as the crankshaft or the pistons. The camshaft turns with the crankshaft such that the intake valves and exhaust valves are opened and closed at the right times. This is important in order to have efficient combustion as well as high engine performance, as this is the point at which gases are able to be exchanged in the chamber. The lobes on the camshaft, the ones that depress the lifters and the rocker arms, move the valves into action, to allow air and fuel to enter and exhaust gases to leave. Knowing the use of the camshaft helps one in understanding how this component in a car engine functions and even affects power and fuel economy.

Understanding Spark Plugs and Their Importance

The gasoline engine part, known as the spark plug, acts as an engine starter to the mixture of fuel and air within the cylinder. As an element of its features, each spark plug is intended to provide a high-voltage spark that ignites the compressed air mixture into a fire. As a result, this fire expels the piston upwards, resulting in the crankshaft turning and converting energy into propulsion. Having the performance of the engine shielded by spark energy can not be overemphasized if one expects to save on gas miles. These elements need to sustain a high temperature and pressure, while every strike is expected to produce fire all the time. It is important to identify and fix faulty spark plugs and maintain engine parts in order to enable better combustion and longer engine life.

The Function of the Connecting Rod in Engine Mechanics

The engine part that is essential to an internal combustion engine is the connecting rod because it is responsible for joining the piston to the crankshaft. It is tasked with making the necessary adjustments to the movement of the piston, which travels as a result of the bursting of gases, and making the shaft turn. This is a very vital function that enables the engine system to have the vehicle begin to move. Able to withstand high-stress, high-temperature conditions of compression and combustion, the connecting rod has to be built in a way that minimizes the impact of the weight so as not to affect the function and the wasting of energy of the engine. It is extremely important to keep the condition and also examine the connecting rod because it wears out or breaks down and causes great engine damage that renders the entire engine of the vehicle inoperative.

Maintaining Engine Parts for Longevity

Practical Tips for Engine Part Maintenance

As an engine part can break down and lose effectiveness in a car, utmost is to maintain all its parts in perfect condition. By having system checks scheduled from time to time, there is a way to reduce the unnecessary effects of wear and tear on crucial engine components the piston, crankshaft, and camshaft, mainly, among others. For an internal combustion engine to be in good working condition, it is important to ensure that the engine oil is checked and changed as recommended to facilitate the lubrication of the engine, which, since all the parts are mobile, operates with low friction and high temperatures. Apart from that, this ensures the spark plug is free of carbon formation and also avoids the cylinder head, which causes backfire, ensuring proper combustion. Moreover, regularly monitoring the wear of intake as well as the exhaust valves would help control the compression in the combustion chamber, too, since it is also important for the engine's operation.

Cost-Saving Strategies for Engine Repairs

Repair of engine parts may have good value. Nonetheless, someone wise would always find a way to reduce these costs. For example, planning and investing money spent on replacing worn components of an engine part and procuring them from better manufacturers and suppliers would go a long way in enhancing these strategies. Maintenance and timely identification of problems also help to correct grave errors commonly known as engine failures. Examples include replacing the water pump to prevent overheating and maintaining the timing chain to prevent premature engine stress, such as knocking. Moreover, the use of diagnostic tools for assessment of any element in the control system is helpful because it helps to determine the damage before repairs become expensive. Maintenance of the car and good engine parts can help owners avoid high costs as they will improve engine health and hence reduce breakdowns.

Trends in Eco-Friendly Engine Parts

Increasing environmental issues have led to the development of engine components that are eco-friendly, with an emphasis on minimizing emissions and maximizing fuel economy. This trend can be observed in the development of internal combustion engines. For instance, efforts for improving the combustion chamber and the cylinder head not only engage the process of enhancing the air and fuel burn, but they also engage the process of complete burning. Such examples include weight reduction through the use of many light materials. Effects of such may include replacing the connecting rod or the block with light materials, for fuel economy. Moreover, advanced back-pressure systems and emission reduction systems contribute immensely to the goal of lessening environmental pollution, as most countries strive to manufacture their cars in cheaper and more eco-friendly ways.

Frequently Asked Questions (FAQs)

How does an engine part like the spark plug work?

The spark plug is a crucial engine part that ignites the air-fuel mixture in the combustion chamber. When the spark plug fires, it creates a small explosion that drives the piston down during the power stroke. This process converts the energy into mechanical energy, propelling the vehicle forward. A well-functioning spark plug ensures efficient combustion, which is vital for the overall performance of the car’s engine. If the spark plug malfunctions, it can lead to incomplete combustion and increased emissions. Regular maintenance of this engine component is essential for optimal engine performance.

What is the role of the cylinder head in car engines?

The cylinder head is a key part of an engine that sits atop the engine block, enclosing the combustion chambers. It contains vital components like the valves of the engine, which control the intake and exhaust of gases. The design of the cylinder head affects the efficiency of the combustion process, influencing the power output and fuel economy of the vehicle’s engine. Additionally, it helps dissipate heat generated during combustion and maintains oil pressure within the engine. Proper sealing and maintenance of the cylinder head are crucial to prevent damage to the engine and ensure longevity.

How do rocker arms function within the valvetrain?

Rocker arms play an essential role in the valvetrain by translating the linear motion of the pushrod into the rotational motion needed to open and close the engine's valves. When the camshaft rotates, it pushes the lifter, which then moves the pushrod that engages the rocker arm. This action allows the intake and exhaust valves to operate at the correct timing during the intake and exhaust strokes. Proper function of the rocker arms ensures that the engine breathes efficiently, allowing for optimal performance. Regular inspection of these components can help prevent issues like valve float or misalignment.

What components are involved in the fuel injection process?

Fuel injection is a crucial aspect of modern engines that involves several components working together to deliver the correct air-fuel mixture to the combustion chamber. Key parts include the fuel pump, fuel injectors, and the intake manifold. The fuel pump delivers fuel from the tank to the injectors, which spray a fine mist into the intake manifold. This process ensures that the air-fuel mixture is adequately mixed before entering the cylinder. A well-functioning fuel injection system enhances engine efficiency, reduces emissions, and improves throttle response. Regular maintenance and diagnostics can help detect issues that may cause poor fuel delivery.

What is the significance of the timing chain in an engine?

The timing chain is a crucial component that synchronizes the rotation of the crankshaft and camshaft, ensuring that the engine operates smoothly. It maintains the precise timing needed for the valves to open and close at the correct intervals during the intake and exhaust strokes. A malfunctioning timing chain can lead to serious damage to the engine, including bent valves or even catastrophic engine failure. Regular inspection and maintenance of the timing chain are essential to prevent wear and tear that could affect the engine’s performance. In some engines, a timing belt may serve the same purpose, but generally requires more frequent replacement.

6BT5.9 Mechanical Engine Parts Fan 4931795US$ 30.00 - 35.00MOQ: 1 PieceHunan Shanbuzhuanshuizhuan Power Technology Co.,Ltd1 Yr

6BT5.9 Mechanical Engine Parts Fan 4931795US$ 30.00 - 35.00MOQ: 1 PieceHunan Shanbuzhuanshuizhuan Power Technology Co.,Ltd1 Yr China Auto Bus Automotive Engine Parts 3928797 3905806 Block EngineUS$ 1063.4 - 1063.4MOQ: 1 PieceHS Electrical Technology Co,LTD3 Yrs

China Auto Bus Automotive Engine Parts 3928797 3905806 Block EngineUS$ 1063.4 - 1063.4MOQ: 1 PieceHS Electrical Technology Co,LTD3 Yrs Diesel Engine Parts O-ring 5e8771 Fit For CaterpillarUS$ 36.5 - 40MOQ: 6 PiecesCertification: CE, ISO9001: 2000Type: Other, sleeveWarranty: 3-12 monthsApplication: ExcavatorHubei Kingland Industrial Co., Ltd.1 Yr

Diesel Engine Parts O-ring 5e8771 Fit For CaterpillarUS$ 36.5 - 40MOQ: 6 PiecesCertification: CE, ISO9001: 2000Type: Other, sleeveWarranty: 3-12 monthsApplication: ExcavatorHubei Kingland Industrial Co., Ltd.1 Yr VOLVO Engine Parts Rocker Arms 20964528, 21732658. Volvo PentaNegotiableMOQ: 1 PieceBrand Name: for volvo pentaModel Number: 20964528, 21732658Ningbo Qiuning Trading Co., Ltd3 Yrs

VOLVO Engine Parts Rocker Arms 20964528, 21732658. Volvo PentaNegotiableMOQ: 1 PieceBrand Name: for volvo pentaModel Number: 20964528, 21732658Ningbo Qiuning Trading Co., Ltd3 Yrs Fuel Tank Cap for Ship Accessory Marine Engine Part CraftUS$ 437 - 437MOQ: 1 PieceWuxi Rongou Technology Development Co. Ltd.3 Yrs

Fuel Tank Cap for Ship Accessory Marine Engine Part CraftUS$ 437 - 437MOQ: 1 PieceWuxi Rongou Technology Development Co. Ltd.3 Yrs New Product Auto Engine Parts Hydraulic Power Steering Rack 57700-1E000 for Hyundai Accent 2005NegotiableMOQ: 10 PiecesPurpose: for replace/repairColor: Pictures ShowingXiAn Wisdom Computer Info&tech Co., Ltd8 Yrs

New Product Auto Engine Parts Hydraulic Power Steering Rack 57700-1E000 for Hyundai Accent 2005NegotiableMOQ: 10 PiecesPurpose: for replace/repairColor: Pictures ShowingXiAn Wisdom Computer Info&tech Co., Ltd8 Yrs 1013 Engine Parts Crankshaft Seal 04253373 /04253333US$ 6.00 - 10.00MOQ: 1 UnitCondition: Newwarranty: 3 Monthsweight (kg): 2Jining Pinbo Import And Export Co.,ltd.1 Yr

1013 Engine Parts Crankshaft Seal 04253373 /04253333US$ 6.00 - 10.00MOQ: 1 UnitCondition: Newwarranty: 3 Monthsweight (kg): 2Jining Pinbo Import And Export Co.,ltd.1 Yr Cylinder Diesel Engine Parts Turning Parts Factory Broaching, Drilling, EtchingNegotiableMOQ: 100 PiecesBrand Name: JunzhuPlace of Origin: ChinaShijiazhuang Junzhu Technology Co., Ltd1 Yr

Cylinder Diesel Engine Parts Turning Parts Factory Broaching, Drilling, EtchingNegotiableMOQ: 100 PiecesBrand Name: JunzhuPlace of Origin: ChinaShijiazhuang Junzhu Technology Co., Ltd1 Yr Fatigue Resistance POM 3010 Raw Material With High Impact for Engineering PartsUS$ 2.9 - 3.9MOQ: 25 KilogramsBrand Name: TenacPlace of Origin: ChinaModel Number: 3010Suzhou Yifuhui New Material Co., Ltd.3 Yrs

Fatigue Resistance POM 3010 Raw Material With High Impact for Engineering PartsUS$ 2.9 - 3.9MOQ: 25 KilogramsBrand Name: TenacPlace of Origin: ChinaModel Number: 3010Suzhou Yifuhui New Material Co., Ltd.3 Yrs Heavy Duty Metal Shredder Aluminum Extrusions Engine Parts Gearboxes CrusherUS$ 18600MOQ: 1 SetMaterial: Alloy SteelCertification: CE, ISODrive: ElectricUsage: MetalHenan Walle Industry Co., Ltd1 Yr

Heavy Duty Metal Shredder Aluminum Extrusions Engine Parts Gearboxes CrusherUS$ 18600MOQ: 1 SetMaterial: Alloy SteelCertification: CE, ISODrive: ElectricUsage: MetalHenan Walle Industry Co., Ltd1 Yr TPU German BSF C95A50 Wear-resistant Low Temperature-resistant Aging-resistant Automotive Engineering PartsUS$ 1.5 - 2MOQ: 25 KilogramsColor: WhiteMolecular Principal Chain: OtherMechanical properties: Long-term heat resistance 100°C (electriAging resistance: Good UV and ozone resistanceShanghai Lechangrong Plastics Co., Ltd.1 Yr

TPU German BSF C95A50 Wear-resistant Low Temperature-resistant Aging-resistant Automotive Engineering PartsUS$ 1.5 - 2MOQ: 25 KilogramsColor: WhiteMolecular Principal Chain: OtherMechanical properties: Long-term heat resistance 100°C (electriAging resistance: Good UV and ozone resistanceShanghai Lechangrong Plastics Co., Ltd.1 Yr Precision Machined Titanium Alloy Bar GR5/GR2 Aerospace Grade for Aircraft Engine Parts Experienced ManufacturerNegotiableMOQ: 100 KilogramsSurface Treatment: Other, Bright rodShape: BarColor: SilverMaterial: Other, TitaniumWuxi Weiman Gaodeng Special Steel Co., Ltd.1 Yr

Precision Machined Titanium Alloy Bar GR5/GR2 Aerospace Grade for Aircraft Engine Parts Experienced ManufacturerNegotiableMOQ: 100 KilogramsSurface Treatment: Other, Bright rodShape: BarColor: SilverMaterial: Other, TitaniumWuxi Weiman Gaodeng Special Steel Co., Ltd.1 Yr POM Asahi Kasei 9054 Low Warpage Low Viscosity High Flow Antistatic Engineering Parts POM Raw MaterialUS$ 1.5 - 1.8MOQ: 25 KilogramsBrand Name: Asahi KaseiPlace of Origin: United StatesModel Number: 9054Density: 1.41 g/cm³Shanghai Liangrun International Trade Co., Ltd.1 Yr

POM Asahi Kasei 9054 Low Warpage Low Viscosity High Flow Antistatic Engineering Parts POM Raw MaterialUS$ 1.5 - 1.8MOQ: 25 KilogramsBrand Name: Asahi KaseiPlace of Origin: United StatesModel Number: 9054Density: 1.41 g/cm³Shanghai Liangrun International Trade Co., Ltd.1 Yr SKF NSK Koyo INA NTN Bearing/Taper Roller Bearing/Roller Bearing/Rolling Bearing for Auto Parts Car Accessories Engine Parts Auto Spare Part Water Pump ValveNegotiableMOQ: 500 PiecesBrand Name: Imported bearingsBeijing SKF Bearing Trading Co., Ltd.1 Yr

SKF NSK Koyo INA NTN Bearing/Taper Roller Bearing/Roller Bearing/Rolling Bearing for Auto Parts Car Accessories Engine Parts Auto Spare Part Water Pump ValveNegotiableMOQ: 500 PiecesBrand Name: Imported bearingsBeijing SKF Bearing Trading Co., Ltd.1 Yr Termostat For SUZUKI Parts No.3599763NegotiableMOQ: 100 PiecesModel Number: 3599763Ruian Yaxin Imp & Exp Co.,Ltd1 Yr

Termostat For SUZUKI Parts No.3599763NegotiableMOQ: 100 PiecesModel Number: 3599763Ruian Yaxin Imp & Exp Co.,Ltd1 Yr K38 K50 Diesel Engine Parts Oil Seal 185747 Mining Construction Machinery Marine Diesel Engine Parts 185747US$ 4 - 10MOQ: 1 Piecewarranty: 6 monthsweight (kg): 0.1video outgoing-inspection: Providedmachinery test report: ProvidedHunan Shanbuzhuanshuizhuan Power Technology Co.,Ltd1 Yr

K38 K50 Diesel Engine Parts Oil Seal 185747 Mining Construction Machinery Marine Diesel Engine Parts 185747US$ 4 - 10MOQ: 1 Piecewarranty: 6 monthsweight (kg): 0.1video outgoing-inspection: Providedmachinery test report: ProvidedHunan Shanbuzhuanshuizhuan Power Technology Co.,Ltd1 Yr Heavy Equipment Diesel Engine Parts 5580859 Drive PulleyUS$ 28.00 - 35.00MOQ: 1 Piecewarranty: 3 monthsweight (kg): 3.1video outgoing-inspection: Providedmachinery test report: ProvidedHunan Shanbuzhuanshuizhuan Power Technology Co.,Ltd1 Yr

Heavy Equipment Diesel Engine Parts 5580859 Drive PulleyUS$ 28.00 - 35.00MOQ: 1 Piecewarranty: 3 monthsweight (kg): 3.1video outgoing-inspection: Providedmachinery test report: ProvidedHunan Shanbuzhuanshuizhuan Power Technology Co.,Ltd1 Yr Original Quality KAT-50 Engine Part Camshaft 3066898 3066899US$ 980.00 - 1080.00MOQ: 1 Piecewarranty: 6 Monthsweight (kg): 25video outgoing-inspection: Providedmachinery test report: ProvidedHunan Shanbuzhuanshuizhuan Power Technology Co.,Ltd1 Yr

Original Quality KAT-50 Engine Part Camshaft 3066898 3066899US$ 980.00 - 1080.00MOQ: 1 Piecewarranty: 6 Monthsweight (kg): 25video outgoing-inspection: Providedmachinery test report: ProvidedHunan Shanbuzhuanshuizhuan Power Technology Co.,Ltd1 Yr High Performance Bus Engine Parts J41C1-1115340 Stop Oil CylinderNegotiableMOQ: 1 PieceHS Electrical Technology Co,LTD3 Yrs

High Performance Bus Engine Parts J41C1-1115340 Stop Oil CylinderNegotiableMOQ: 1 PieceHS Electrical Technology Co,LTD3 Yrs NTA855 Engine Parts 3076811 PistonUS$ 32.00 - 35.00MOQ: 1 Piecewarranty: 3 monthsweight (kg): 3video outgoing-inspection: Providedmachinery test report: ProvidedHunan Shanbuzhuanshuizhuan Power Technology Co.,Ltd1 Yr

NTA855 Engine Parts 3076811 PistonUS$ 32.00 - 35.00MOQ: 1 Piecewarranty: 3 monthsweight (kg): 3video outgoing-inspection: Providedmachinery test report: ProvidedHunan Shanbuzhuanshuizhuan Power Technology Co.,Ltd1 Yr Verified Buyer submitted an RFQ for Diesel Engine Parts Crankshaft 6240-31-1100 Fit For Komatsu SAA6D170E2025-11-13 10:49:23

Verified Buyer submitted an RFQ for Diesel Engine Parts Crankshaft 6240-31-1100 Fit For Komatsu SAA6D170E2025-11-13 10:49:23 Importer submitted an RFQ for T436932 Glow Plug Perkins Engine parts Genuine for 100 and 400 engines2025-11-12 07:51:12

Importer submitted an RFQ for T436932 Glow Plug Perkins Engine parts Genuine for 100 and 400 engines2025-11-12 07:51:12 Operations Head verified certifications for 3056182 Construction Machinery K19 Diesel Engine Part Heater 30561822025-11-12 12:34:43

Operations Head verified certifications for 3056182 Construction Machinery K19 Diesel Engine Part Heater 30561822025-11-12 12:34:43 Purchasing Director requested specs for Made in China auto Bus Parts M7600-1306004B Original Bus Engine Thermostat2025-11-13 05:15:35

Purchasing Director requested specs for Made in China auto Bus Parts M7600-1306004B Original Bus Engine Thermostat2025-11-13 05:15:35 Importer requested specs for Perkins Engine parts Genuine T400215 Valve Seat Insert for 2806TAG1 (A), 2806TAG2 (A)2025-11-14 00:40:33

Importer requested specs for Perkins Engine parts Genuine T400215 Valve Seat Insert for 2806TAG1 (A), 2806TAG2 (A)2025-11-14 00:40:33 Operations Head negotiating terms for Diesel Engine Parts Valve Lifter 574-4543 Fit For Caterpillar 3512/35162025-11-13 14:07:51

Operations Head negotiating terms for Diesel Engine Parts Valve Lifter 574-4543 Fit For Caterpillar 3512/35162025-11-13 14:07:51 Sourcing Manager placed an order for Construction Machinery Truck 4BT3.9 4BTA Diesel Engine Parts Aftercooler 493850722 hours ago

Sourcing Manager placed an order for Construction Machinery Truck 4BT3.9 4BTA Diesel Engine Parts Aftercooler 493850722 hours ago Truck Heavy Equipment ISL 8.9 QSL8.9 6L Engine Parts Piston 5267632US$ 32.00 - 38.00MOQ: 1 PieceHunan Shanbuzhuanshuizhuan Power Technology Co.,Ltd1 Yr

Truck Heavy Equipment ISL 8.9 QSL8.9 6L Engine Parts Piston 5267632US$ 32.00 - 38.00MOQ: 1 PieceHunan Shanbuzhuanshuizhuan Power Technology Co.,Ltd1 Yr 4BT ISDE 4080554 Diesel Engine Parts HoseUS$ 18.00 - 20.00MOQ: 1 Piecewarranty: 6 Monthsweight (kg): 2video outgoing-inspection: Providedmachinery test report: ProvidedHunan Shanbuzhuanshuizhuan Power Technology Co.,Ltd1 Yr

4BT ISDE 4080554 Diesel Engine Parts HoseUS$ 18.00 - 20.00MOQ: 1 Piecewarranty: 6 Monthsweight (kg): 2video outgoing-inspection: Providedmachinery test report: ProvidedHunan Shanbuzhuanshuizhuan Power Technology Co.,Ltd1 Yr Heavy Equipment Marine Engine QSK60 Diesel Engine Parts Bellows 4080158US$ 42.00 - 55.00MOQ: 1 Piecewarranty: 6 monthsweight (kg): 4.586video outgoing-inspection: Providedmachinery test report: ProvidedHunan Shanbuzhuanshuizhuan Power Technology Co.,Ltd1 Yr

Heavy Equipment Marine Engine QSK60 Diesel Engine Parts Bellows 4080158US$ 42.00 - 55.00MOQ: 1 Piecewarranty: 6 monthsweight (kg): 4.586video outgoing-inspection: Providedmachinery test report: ProvidedHunan Shanbuzhuanshuizhuan Power Technology Co.,Ltd1 Yr