304 Stainless Steel Insights & Buyer's Guide

If you happen to have materials that give excellent strength, flexibility, and performance at the same time, 304 stainless steel, without a doubt, tops the list. From across all the industries, this alloy is the most commonly employed one because of its outstanding resistance to rust, good ability for forming, and a broad scope of usefulness. Whether one deals with a stainless steel sheet(Click here to read more), a coil, a rod, or a stainless steel pipe, it is fundamental to gain knowledge of the characteristics of 304 stainless steel to choose the appropriate material for a job. The present paper aims to thoroughly discuss the properties of 304 stainless steel, describe the process of its manufacture, and analyze particularly those aspects of its comparison to other stainless steel types that will contribute to making the right decisions.

Overview of 304 Stainless Steel

Why Should One Know About 304 Stainless Steel?

Perhaps the most common stainless steel available is the 304 stainless steel, as it is an austenitic stainless steel that equally boasts a blend of high mechanical strength and serviceability alongside excellent corrosion resistance. It is composed of roughly 18 percent chromium and 8 percent nickel and is commonly referred to as the 18/8 stainless steel due to these remarkable attributes. For instance, the chromium helps in the development of a layer of protective oxide coating, and as for the nickel, it gives the steel its fabric performance and bolts. This general-purpose alloy is pitting and crevice corrosion resistant; therefore, it’s often used in certain types of environments that are prone to chloride attacks. Additionally, one cannot underestimate such steel as it is able to exist in a number of other forms, including 304L and 304H, and in each case, the permissible carbon levels and maximum operating temperatures for the materials differ.

Introduction to the Classes of Stainless Steel

Based on the arrangement of their constituent elements and the complexity of construction, stainless steels may be subdivided into a number of grades. In this way, different materials can be manufactured to match the demands of a particular industry, such as enhancing flexibility, corrosion resistance, or strength. Stainless steels such as 304 and 316 belong to the austenitic class and are classified as non-magnetic and highly resistant to oxidation and aggressive environments. Most notably, the absence of molybdenum in 316 stainless steel makes it less resistant to chemicals like chlorides and stress corrosion cracking than 304. Different grades like 321 and 304 H have additional advantages, for example, those relevant in the design of equipment envisaged to be used at high temperature. Thus, the selection of a stainless steel for slump prevention is very important.

Why 304 Stainless Steel is Essential for Industries

There is no denying that 304 stainless steel is one of the key materials that serves many sectors due to its extensive use and flexibility. For example, in construction, this material is popular for corrosion-resistant and elegant design architectural works and facades of industries. Without this base material, the food processing industry wouldn't dare attempt most of its operations, as this class of alloys is resistant to corrosion and is easy to maintain. In medicine, the fact that steels are inert and do not corrode makes them an ideal candidate for surgical tools and even implants. Furthermore, 304 stainless steel also plays a role in the production of chemical processing equipment because it provides the heat resistance that is required for use in aggressive environments. The ubiquity of its application clearly emphasizes its value as a material that cannot be replaced within different industries.

Properties of 304 Stainless Steel

Mechanical Strength: Tensile and Yield Strength

Mechanical strength in terms of tensile and yield strength is the most renowned property of 304 stainless steel. This austenitic stainless steel has a tensile strength in the range of 515 to 700 MPa and a yielding strength of 205 MPa. This property can be almost entirely explained by the optimal selection of its chemical composition, providing both chromium content, which imparts strength, and nickel, which increases ductility. These features primarily draw 304 stainless steel for engineering applications, where significant stresses do not cause plastic deformation. It is also this alloy's optimum strength under extreme conditions that makes it so popular in varied industries, such as building materials and manufacturing, among others.

Corrosion Resistance Properties

An important characteristic of 304 stainless steel is its superb resistance to corrosive attack, which is attributed to the high chromium levels in the composition. The reason is that the chromium helps to form a protective film on the surface. Moreover, the stainless steel is also able to resist the kind of corrosion called pitting or crevice corrosion, particularly where chloride is present. On the other hand, it must be noted that 304 stainless steel lacks the content of molybdenum present in 316 stainless steel, which enhances resistance to chlorides, although it can still serve in relatively mild environments. Due to this factor, it is often preferred when used in food, chemical, and corrosive equipment, amongst others.

Disadvantages to Manufacturing

The manufacturing industry experiences enhancement when 304 stainless steel is introduced due to its characteristics, specifically, its propensity to weld and be shaped. Being an austenitic steel, this type of stainless steel can be welded with all the common methods without the need for treatment or annealing after welding, which is very desirable in some construction or fabrication activities. It can also be fabricated into more complicated forms due to the ability of stainless steel to be cold worked, which is most important in its wider application. It is recommended to pay attention, however, to avoid any touching between the surfaces of the stainless steel and any mild steel in the course of the work. This is because it will result in corrosion. It is only logical to use tools that are meant for stainless steel only to ensure that the alloy gets to the finished product in good condition.

Development of 304 Stainless Steel Manufacturing

Procedures for Joining 304 Stainless Steel

The popularity of welding type 304 stainless steel stems from its great weldability properties, which emanate from the nature of this steel, which is austenitic. Due to the chromium-nickel alloy chemical structure of this steel, it is possible to weld it using processes such as tungsten inert gas welding (TIG), metal inert gas welding (MIG), and even stick welding. Such methods allow to creation of secure and reliable joints without affecting the properties of the materials. Nonetheless, it is important to note that stainless steel should be handled with tools meant specifically for stainless steel. This is because the issue of rust on the surfaces exposed to the aggressive media is usually encountered in galvanized structures. Whether structures are normally passable in the sea or beyond the level, it’s advisable to treat welded surfaces. For this purpose, pickling and passivation are often carried out.

Caliber of Cold Performance

Due to its suitability for complex fabricated shapes and designs, 304 stainless steel can be readily cold worked. Cold working is a process of working a metal at room temperature that modifies the properties of the alloy, such as tensile strength and hardness, without changing the chemical makeup. As cold working is done to the metal, such components do not suffer from the problem of stress corrosion cracking due to the non-formation of carbide precipitation, making it more useful for components that require high strength. Cold working, in fact, due to the absence of temperature, preserves the good property of such an alloy against corrosion, as well as permits the reproduction of parts to a high precision. Automotive, aerospace, and many other industries exploit the nature of materials in making tough and high-performance structures.

Machinability of 304 Stainless Steel

The austenitic structure of the 304 stainless steel in some respect has its advantages as well as challenges, making the steel difficult to machine. Even the fact that it is not as machinable as some other steel grades, i.e., 303, the same can be achieved properly with the use of the right methods. Since excessive work hardening of the alloy would result in a shortened tool life, sharp cutting tools and careful selection of speeds should be maintained. Coolants and lubricants are also indispensable in the quest to extend tool life and provide better finishing. However hard it may seem, it is equally true that the range of components that can be produced from 304 stainless steel with a corresponding higher vector of details and accuracy enhances its role in the stainless steel versatility across multiple industries.

Applications of 304 Stainless Steel

Construction and Architectural Applications

In construction and architecture, the usage of 304 stainless steel is very high, mainly because of its anodic protection in the form of a film and its nice appearance. This austenitic stainless steel fits best with the large amounts of moisture and dirt, as this category of stainless steel contains chromium as the antioxidant. This property is responsible for the long durability of the structures. Therefore, when building facades, handrails, or roofs, this material is suitable, since it stands harsh weather elements without deterioration. It is also a plus that 304 stainless steel is easy to work with, and the parts can be easily joined together, which allows for complicated geometrical shapes in construction, enhancing function and form. Similarly, there are many types of stainless steel, such as the 304 grade, which comes in an assortment of finishes and grades, like 304L and 304H, that have been designed to achieve certain goals in architecture, making it one of the most sought-after materials in creating structures in the modern era.

Food Processing Equipment at the same time.

The food industry emphasizes a lot of non-reactivity and easy cleaning of 304 stainless steel. This is simply because of how the food industry is structured. It requires high sanitation for safety purposes, and hence, the agitated cleaning of any apparatus is overtaken by processes that involve stainless steel. It is resistant to pitting and crevice corrosion, and this is especially helpful when exposed to active substances such as food or cleaning agent chemicals. This is achievable through the addition of chromium and nickel in the alloy, which enhances corrosion resistance and deformation resistance in the material. Storage tanks, conveying systems, and agitators are among the various equipment that also take advantage of the inherent mechanical strength of 304 stainless steel and its low susceptibility to stress corrosion. Not to forget that it meets all the ASTM specifications, besides observing the food safety protocols that are admirable and needed to ensure that no food is contaminated at any stage of processing in the factory.

Medical Instruments and Tools

The medical sector makes considerable use of 304 stainless steel due to its inert and anti-rusting characteristics, which render it useful in the production of surgical tools, prosthetics, and various testing apparatus. Because of its austenitic nature, which means that it contains a lot of chromium and nickel, this alloy does not corrode or rust, which, in turn, makes it feasible for making sterilizable and long-lasting medical devices. Its extroverted quality or non-reactivity is necessary for many applications where it is necessary to have very strong materials, especially in the case of surgery, where the material cannot be deformed. Moreover, the ability of the material, 304 stainless steel, to be cold-formed makes it possible to produce very detailed medical instruments in a non-harmful manner. Such quality properties are achieved due to the presence of a dual certification system in the form of various categories of materials, such as 304L, which can ensure higher levels of standards in the appropriate medical conditions.

Frequently Asked Questions (FAQs)

What is the chemical composition of 304 stainless steel?

Most of the 304 stainless steel material is iron, with carbon having a content of more or less 0.08%. It also has high levels of chromium 18%, and nickel 8% both of which play a very important role in ensuring that it is well protected against corrosion and also enhances its malleability. Furthermore, nickel in the alloy increases the silver metal’s resistance to many corrosion-inducing substances to such an extent that it is employed for many applications. This is an austenitic alloy, which indicates that its crystals form in a face-centered cubic structure, which has its own structure that allows for reasonable strength and ductility. There are also variations of grade 304 with lower carbon contents, such as 304L, which can be used in case of welding considerations, with no concern for carbide formation, a scenario that would otherwise be avoided.

What are the mechanical properties of 304 stainless steel?

The mechanical properties of 304 stainless steel include a tensile strength of approximately 520 MPa and a yield strength of about 215 MPa. These properties make it suitable for various structural applications where moderate strength is required. Its elongation percentage is around 40%, indicating good ductility and formability. Additionally, 304 stainless steel exhibits excellent resistance to pitting corrosion and oxidation in intermittent service. When comparing 304 and 316 stainless steel, it's important to note that 316 offers higher corrosion resistance due to the addition of molybdenum, making it preferable for marine applications.

How does 304 vs 316 stainless steel differ?

Stainless steel alloys such as 304 and 316 have different chemical properties, which make them quite distinct from each other. They are both austenitic levels of resistance. However, 316 stainless steel has molybdenum in it, which is necessary when dealing for example with marine environments, since this grade is more pitting-and stress corrosion crack-resistant. On the other hand, in 304 stainless steel, there is no content of molybdenum, meaning, it is susceptible to some chemicals more than other types. Nonetheless, in most cases and in terms of cost such as in this example, 304 grade offers enough corrosion protection. While choosing 304 or 316, one should weigh the service conditions as well as performances to be provided specifically for the described condition.

What is the significance of 304H and 304L grades?

304H is best suited for pressure vessels and heat exchangers where high strength is desired at high temperatures. This type has a higher Carbon content than 304, which helps to boost its strength; however, it can reduce the weldability of this stainless steel. 304L, on the flip side, is a variant of low carbon and is great when carbide precipitation is to be eliminated during welding. Thus, 304L comes into play when such a need for superb weldability and corrosion resistance arises. While both of these grades are utilized in many different production methods, such as welding and forming, it is essential to choose the grade that provides the best mechanical performance, as mechanical properties that perform well in a given environment are not mechanical properties of interest alone.

How can fabrication processes affect the properties of 304 stainless steel?

Methods like cold working and welding are some of the common factors that can alter the mechanical properties as well as the performance of 304 stainless steel. Cold working increases material strength and hardness through work hardening, and this makes it suitable for high-stress working conditions. Although excess cold working degrades ductility. In welding, metals need to be clean to prevent contamination of the stainless steel weld, as the presence of foreign particles in the alloy weld decreases its resistance to corrosion. Also, the manner in which the metal is handled and worked on should uphold the grain structure or cause problems such as SCC. It therefore implies these effects assist in obtaining the required properties of the final products.

Industrial Pneumatic V-Type Ball Valve With 304/316 Stainless Steel Body for Chemical IndustryNegotiableMOQ: 1 SetApplication: Industrial Usage, Water Industrial UsageType: V Type Ball ValveOrigin: ChinaShanghai CAMP Environmental Protection Technology Co., Ltd.1 Yr

Industrial Pneumatic V-Type Ball Valve With 304/316 Stainless Steel Body for Chemical IndustryNegotiableMOQ: 1 SetApplication: Industrial Usage, Water Industrial UsageType: V Type Ball ValveOrigin: ChinaShanghai CAMP Environmental Protection Technology Co., Ltd.1 Yr Stainless Steel HouseUS$ 10 - 120MOQ: 1 SetPlace of Origin: Shanghai, ChinaBrand Name: sinoarchModel Number: TE--0098Material: Other, Steel, SteelSinoarch Shanghai Co., Ltd.5 Yrs

Stainless Steel HouseUS$ 10 - 120MOQ: 1 SetPlace of Origin: Shanghai, ChinaBrand Name: sinoarchModel Number: TE--0098Material: Other, Steel, SteelSinoarch Shanghai Co., Ltd.5 Yrs 304 Stainless Steel Rope Mesh Anti-fall NetUS$ 9.5 - 10MOQ: 1 Square MeterType: Stainless Steel Plain Wire MeshCertification: ISO9001, OtherApplication: Protecting Mesh, Fence MeshTechnique: WovenAnping Boli Wire Mesh Hardware Co.,ltd2 Yrs

304 Stainless Steel Rope Mesh Anti-fall NetUS$ 9.5 - 10MOQ: 1 Square MeterType: Stainless Steel Plain Wire MeshCertification: ISO9001, OtherApplication: Protecting Mesh, Fence MeshTechnique: WovenAnping Boli Wire Mesh Hardware Co.,ltd2 Yrs Ss304, 304L, 321, 316L Cold Rolled 304 Stainless Steel Strip/Coil PriceNegotiableMOQ: 1 TonPlace of Origin: ChinaModel Number: 304, 304L, 321, 316L, 317L, 309s, 310sApplication: Automotive, solar energy, metal products, household appliances, precision electronics, containers, machinery manufacturing, elevators, sanitary ware, rail transit, pressure vessels, architectural decoration, nuclear power, catering kitchenware, chemical equipment, daily electrical appliances, food machinery, structural pipe, etcTechnique: Cold RolledJiangsu Zhonggongte Metallurgical Technology Co., Ltd.1 Yr

Ss304, 304L, 321, 316L Cold Rolled 304 Stainless Steel Strip/Coil PriceNegotiableMOQ: 1 TonPlace of Origin: ChinaModel Number: 304, 304L, 321, 316L, 317L, 309s, 310sApplication: Automotive, solar energy, metal products, household appliances, precision electronics, containers, machinery manufacturing, elevators, sanitary ware, rail transit, pressure vessels, architectural decoration, nuclear power, catering kitchenware, chemical equipment, daily electrical appliances, food machinery, structural pipe, etcTechnique: Cold RolledJiangsu Zhonggongte Metallurgical Technology Co., Ltd.1 Yr 304 Stainless Steel Wire Rope Zoo Mesh Flexible Knotted Cable Rope Net for Animals ProtectionNegotiableMOQ: 50 Square MetersMaterial: Other, 304/316Type: Stainless Steel Plain Wire MeshApplication: Construction Wire Mesh, Protecting Mesh, Decorative Mesh, Fence MeshTechnique: WovenHebei Julong Wire Mesh Co., Ltd.1 Yr

304 Stainless Steel Wire Rope Zoo Mesh Flexible Knotted Cable Rope Net for Animals ProtectionNegotiableMOQ: 50 Square MetersMaterial: Other, 304/316Type: Stainless Steel Plain Wire MeshApplication: Construction Wire Mesh, Protecting Mesh, Decorative Mesh, Fence MeshTechnique: WovenHebei Julong Wire Mesh Co., Ltd.1 Yr EP Sanitary Standard Stainless Steel Pipe – No Dead Angle, Full Penetration Weld, Traceable 304 Stainless Steel Bright TubeUS$ 2535MOQ: 1 TonPlace of Origin: ChinaCertification: OtherThickness: 0.6, 5Application: Other, Construcion/Building /Food industryZhongzheng Stainless Steel Co., Ltd.1 Yr

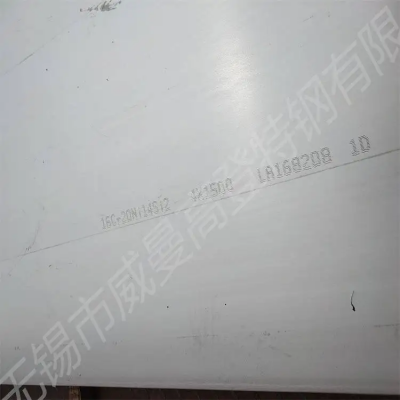

EP Sanitary Standard Stainless Steel Pipe – No Dead Angle, Full Penetration Weld, Traceable 304 Stainless Steel Bright TubeUS$ 2535MOQ: 1 TonPlace of Origin: ChinaCertification: OtherThickness: 0.6, 5Application: Other, Construcion/Building /Food industryZhongzheng Stainless Steel Co., Ltd.1 Yr Customized Cold/Hot Rolled 304 304L 316 316L 410 430 Stainless Steel PlateNegotiableMOQ: 1 TonType: Stainless Steel PipesShape: SquareTechnique: Other, Hot rolling/cold rollingWuxi Weiman Gaodeng Special Steel Co., Ltd.1 Yr

Customized Cold/Hot Rolled 304 304L 316 316L 410 430 Stainless Steel PlateNegotiableMOQ: 1 TonType: Stainless Steel PipesShape: SquareTechnique: Other, Hot rolling/cold rollingWuxi Weiman Gaodeng Special Steel Co., Ltd.1 Yr 304 Stainless Steel Light Duty Storage RackNegotiableMOQ: 1 SetUsage: IndustrialHeight: 0-5mClosed: OpenServiceability: Common UseGusu District Qiusheng Commercial Equipment Firm1 Yr

304 Stainless Steel Light Duty Storage RackNegotiableMOQ: 1 SetUsage: IndustrialHeight: 0-5mClosed: OpenServiceability: Common UseGusu District Qiusheng Commercial Equipment Firm1 Yr Multifuction 304 Stainless Steel Dumpling Making MachineUS$ 1,000 - 10,000MOQ: 1 SetCondition: NewType: Other, Dumpling,Samosa & EmpanadaProduction Capacity: 2.5kwPlace of Origin: Shanghai, ChinaShanghai Genyond Technology Co., Ltd.2 Yrs

Multifuction 304 Stainless Steel Dumpling Making MachineUS$ 1,000 - 10,000MOQ: 1 SetCondition: NewType: Other, Dumpling,Samosa & EmpanadaProduction Capacity: 2.5kwPlace of Origin: Shanghai, ChinaShanghai Genyond Technology Co., Ltd.2 Yrs Fully Automatic Autoclave 304 Stainless SteelNegotiableMOQ: 1 PiecePlace of Origin: ChinaAfter-sales Service Provided: Engineers available to service machinery overseasZhongshan ACEYEA Sanitary Ware Co., Ltd.1 Yr

Fully Automatic Autoclave 304 Stainless SteelNegotiableMOQ: 1 PiecePlace of Origin: ChinaAfter-sales Service Provided: Engineers available to service machinery overseasZhongshan ACEYEA Sanitary Ware Co., Ltd.1 Yr 304 Stainless Steel Flash Butt Welding Link ChainNegotiableMOQ: 1 SetChangsong Industrial Equipment Shandong Ltd.2 Yrs

304 Stainless Steel Flash Butt Welding Link ChainNegotiableMOQ: 1 SetChangsong Industrial Equipment Shandong Ltd.2 Yrs 304 Stainless Steel Sesame Seed Skin Peeling and Separating Machine for SaleNegotiableMOQ: 1 SetBrand Name: GelgoogPlace of Origin: ChinaModel Number: GG-QZ1Type: sesame peeling machineHenan Gelgoog Machinery CO,LTD2 Yrs

304 Stainless Steel Sesame Seed Skin Peeling and Separating Machine for SaleNegotiableMOQ: 1 SetBrand Name: GelgoogPlace of Origin: ChinaModel Number: GG-QZ1Type: sesame peeling machineHenan Gelgoog Machinery CO,LTD2 Yrs Corrosion-Resistant Hydraulic Elevator Sluice Dam 304 Stainless Steel Gate Manufacturer Hydraulic Elevator DamUS$ 400 - 460MOQ: 10 Square MetersMaterial: Carbon Steel/multi-grade hydraulic systProduct Grade: AAAsize: 2-10mType: Movable, up and downHengshui Haogu Engineering Materials Co., Ltd.1 Yr

Corrosion-Resistant Hydraulic Elevator Sluice Dam 304 Stainless Steel Gate Manufacturer Hydraulic Elevator DamUS$ 400 - 460MOQ: 10 Square MetersMaterial: Carbon Steel/multi-grade hydraulic systProduct Grade: AAAsize: 2-10mType: Movable, up and downHengshui Haogu Engineering Materials Co., Ltd.1 Yr 304 Stainless Steel Glass Bottle Washing Filling Capping Monoblock Machine 220V Or 380V VoltageNegotiableMOQ: 1 SetPackaging: BottleWarranty: 1 YearAutomatic Grade: AutomaticSupply Ability: 20 sets per monthShandong Gongda Intelligent Equipment Co., Ltd.1 Yr

304 Stainless Steel Glass Bottle Washing Filling Capping Monoblock Machine 220V Or 380V VoltageNegotiableMOQ: 1 SetPackaging: BottleWarranty: 1 YearAutomatic Grade: AutomaticSupply Ability: 20 sets per monthShandong Gongda Intelligent Equipment Co., Ltd.1 Yr 304 Stainless Steel Small Capacity Mozzarella Cheese Cutter Cheese Shredder Slicer GraterNegotiableMOQ: 1 SetType: Other, Fruit and vegetable processing equipmentWarranty: One yearVoltage: Other, 110V 220V 380VPower: 1.5KWJinan Xinyuqi Food Machinery Co., Ltd.1 Yr

304 Stainless Steel Small Capacity Mozzarella Cheese Cutter Cheese Shredder Slicer GraterNegotiableMOQ: 1 SetType: Other, Fruit and vegetable processing equipmentWarranty: One yearVoltage: Other, 110V 220V 380VPower: 1.5KWJinan Xinyuqi Food Machinery Co., Ltd.1 Yr OEM 304 Stainless Steel Perforated Pipes OD50mm Filter Strainer for Pharmaceutical Filtration SystemsUS$ 10.00 - 12.00MOQ: 999 PiecesTechnique: PerforatedModel Number: perforated pipe819r4Hebei Longen Wire Mesh Products Co., Ltd.1 Yr

OEM 304 Stainless Steel Perforated Pipes OD50mm Filter Strainer for Pharmaceutical Filtration SystemsUS$ 10.00 - 12.00MOQ: 999 PiecesTechnique: PerforatedModel Number: perforated pipe819r4Hebei Longen Wire Mesh Products Co., Ltd.1 Yr 304 Stainless Steel Self-Priming Cyclone Dust Removal Octagonal Seasoning Grinder Toothed Disc Rice Pepper Grinder for SaleUS$ 1050 - 2460MOQ: 1 Pieceplace of origin: Henan, Chinabrand name: Panqiproduction capacity: 0-1000voltage: 220v/380v.Henan Panqi Heavy Industry Technology Co., Ltd.1 Yr

304 Stainless Steel Self-Priming Cyclone Dust Removal Octagonal Seasoning Grinder Toothed Disc Rice Pepper Grinder for SaleUS$ 1050 - 2460MOQ: 1 Pieceplace of origin: Henan, Chinabrand name: Panqiproduction capacity: 0-1000voltage: 220v/380v.Henan Panqi Heavy Industry Technology Co., Ltd.1 Yr Quality Anti Corrosion New Fashion Stainless Steel Jewelry Necklace, Bracelet, Earring, Accessories, Rings Etc.NegotiableMOQ: 100 PiecesMaterial: Stainless SteelUsage: Decoration, GiftOccasion: Other, AllTrademark: OEMNantong Zhongmian Commercial Co., Ltd.1 Yr

Quality Anti Corrosion New Fashion Stainless Steel Jewelry Necklace, Bracelet, Earring, Accessories, Rings Etc.NegotiableMOQ: 100 PiecesMaterial: Stainless SteelUsage: Decoration, GiftOccasion: Other, AllTrademark: OEMNantong Zhongmian Commercial Co., Ltd.1 Yr Stainless Steel Liquid Mixing Tank 304/316L for Chemical Pharmaceutical Food Industry With CIP Cleaning SystemNegotiableMOQ: 1 UnitApplication: LiquidCondition: NewApplication Area: Agricultural Chemicals, Chemical, Daily Chemical, Engineering & Construction, Food, Metallurgy&Mineral, PharmaceuticalDongguan Xinbao Machinery Co., Ltd1 Yr

Stainless Steel Liquid Mixing Tank 304/316L for Chemical Pharmaceutical Food Industry With CIP Cleaning SystemNegotiableMOQ: 1 UnitApplication: LiquidCondition: NewApplication Area: Agricultural Chemicals, Chemical, Daily Chemical, Engineering & Construction, Food, Metallurgy&Mineral, PharmaceuticalDongguan Xinbao Machinery Co., Ltd1 Yr Aluminium Stainless Steel Prod Vent Mush Marine Mushroom Cowl VentUS$ 440 - 440MOQ: 1 PieceWuxi Rongou Technology Development Co. Ltd.3 Yrs

Aluminium Stainless Steel Prod Vent Mush Marine Mushroom Cowl VentUS$ 440 - 440MOQ: 1 PieceWuxi Rongou Technology Development Co. Ltd.3 Yrs Space-Saving Stainless Steel Herbal Dispenser for Wellness Centers & Health Stores - Large Capacity Waterproof Cabinet for Herb Sample ManagementUS$ 50 - 300MOQ: 5 CombosMaterial: MetalStyle: ModernCondition: NewTransport Package: Carton BoxLuoyang Hengna Office Furniture Co., Ltd.1 Yr

Space-Saving Stainless Steel Herbal Dispenser for Wellness Centers & Health Stores - Large Capacity Waterproof Cabinet for Herb Sample ManagementUS$ 50 - 300MOQ: 5 CombosMaterial: MetalStyle: ModernCondition: NewTransport Package: Carton BoxLuoyang Hengna Office Furniture Co., Ltd.1 Yr Frank Stainless Steel HouseUS$ 10 - 120MOQ: 1 SetPlace of Origin: Shanghai, ChinaBrand Name: sinoarchModel Number: TE--0098Material: Other, Steel, SteelSinoarch Shanghai Co., Ltd.5 Yrs

Frank Stainless Steel HouseUS$ 10 - 120MOQ: 1 SetPlace of Origin: Shanghai, ChinaBrand Name: sinoarchModel Number: TE--0098Material: Other, Steel, SteelSinoarch Shanghai Co., Ltd.5 Yrs Industrial Stainless Steel HouseUS$ 10 - 120MOQ: 1 SetPlace of Origin: Shanghai, ChinaBrand Name: sinoarchModel Number: TE--0098Material: Other, Steel, SteelSinoarch Shanghai Co., Ltd.5 Yrs

Industrial Stainless Steel HouseUS$ 10 - 120MOQ: 1 SetPlace of Origin: Shanghai, ChinaBrand Name: sinoarchModel Number: TE--0098Material: Other, Steel, SteelSinoarch Shanghai Co., Ltd.5 Yrs Single Stainless Steel HouseUS$ 10 - 120MOQ: 1 SetPlace of Origin: Shanghai, ChinaBrand Name: sinoarchModel Number: TE--0098Material: Other, Steel, SteelSinoarch Shanghai Co., Ltd.5 Yrs

Single Stainless Steel HouseUS$ 10 - 120MOQ: 1 SetPlace of Origin: Shanghai, ChinaBrand Name: sinoarchModel Number: TE--0098Material: Other, Steel, SteelSinoarch Shanghai Co., Ltd.5 Yrs Business Owner is sourcing stainless steel nesting table4 hours ago

Business Owner is sourcing stainless steel nesting table4 hours ago Verified Buyer submitted an RFQ for Magnetic Flap Level Gauge with ±10mm Accuracy, Stainless Steel/PTFE Construction, High-Sealing for Leak-Proof in Harsh Industrial Conditions2025-11-13 04:51:22

Verified Buyer submitted an RFQ for Magnetic Flap Level Gauge with ±10mm Accuracy, Stainless Steel/PTFE Construction, High-Sealing for Leak-Proof in Harsh Industrial Conditions2025-11-13 04:51:22 Verified Buyer requested specs for 304 Stainless Steel Plate / Stainless Steel Sheet 304 With Mirror Surface2025-11-16 01:05:04

Verified Buyer requested specs for 304 Stainless Steel Plate / Stainless Steel Sheet 304 With Mirror Surface2025-11-16 01:05:04 Operations Head verified certifications for Bottom Discharge Valve VTF-88-3 Series, DN25-DN300, Stainless Steel 316L/Carbon Steel, PN10/PN16 Class 150, Manual or Pneumatic Actuation2025-11-14 02:06:15

Operations Head verified certifications for Bottom Discharge Valve VTF-88-3 Series, DN25-DN300, Stainless Steel 316L/Carbon Steel, PN10/PN16 Class 150, Manual or Pneumatic Actuation2025-11-14 02:06:15 Sourcing Manager negotiating terms for 316L Stainless Steel Pressure Sensor for Petrochemical, Power, and Marine Applications Featuring Long-term Stability and Wide Signal Output Options2025-11-15 05:48:52

Sourcing Manager negotiating terms for 316L Stainless Steel Pressure Sensor for Petrochemical, Power, and Marine Applications Featuring Long-term Stability and Wide Signal Output Options2025-11-15 05:48:52 Purchasing Director inquired about Stainless Steel Knife Gate Valve with Fluorine-Lined Material - Corrosion-Resistant for Chemical Processing and Harsh Media Application2025-11-12 00:32:07

Purchasing Director inquired about Stainless Steel Knife Gate Valve with Fluorine-Lined Material - Corrosion-Resistant for Chemical Processing and Harsh Media Application2025-11-12 00:32:07 Procurement Specialist is sourcing Stainless Steel 316L Pressure Sensor with Heat Sink for Extreme Conditions in Petrochemical, Power & Food Processing Industries2025-11-14 20:16:07

Procurement Specialist is sourcing Stainless Steel 316L Pressure Sensor with Heat Sink for Extreme Conditions in Petrochemical, Power & Food Processing Industries2025-11-14 20:16:07 Purchasing Director requested a quote for Stainless steel sink(clean room sink & clean room equipment)2025-11-12 00:23:04

Purchasing Director requested a quote for Stainless steel sink(clean room sink & clean room equipment)2025-11-12 00:23:04 Stainless Steel TableUS$ 50 - 250MOQ: 1 SetMaterial: Other, Metal, Glass,Aluminium,CeramicMetal Type: Stainless SteelAppearance: AntiqueFolded: NoSinoarch Shanghai Co., Ltd.5 Yrs

Stainless Steel TableUS$ 50 - 250MOQ: 1 SetMaterial: Other, Metal, Glass,Aluminium,CeramicMetal Type: Stainless SteelAppearance: AntiqueFolded: NoSinoarch Shanghai Co., Ltd.5 Yrs Folding Stainless Steel TableUS$ 50 - 250MOQ: 1 SetMaterial: Other, Metal, Glass,Aluminium,CeramicMetal Type: Stainless SteelAppearance: AntiqueFolded: YesSinoarch Shanghai Co., Ltd.5 Yrs

Folding Stainless Steel TableUS$ 50 - 250MOQ: 1 SetMaterial: Other, Metal, Glass,Aluminium,CeramicMetal Type: Stainless SteelAppearance: AntiqueFolded: YesSinoarch Shanghai Co., Ltd.5 Yrs Mobile Stainless Steel TablesUS$ 50 - 250MOQ: 1 SetMaterial: Other, Metal, Glass,Aluminium,CeramicMetal Type: Stainless SteelAppearance: AntiqueFolded: NoSinoarch Shanghai Co., Ltd.5 Yrs

Mobile Stainless Steel TablesUS$ 50 - 250MOQ: 1 SetMaterial: Other, Metal, Glass,Aluminium,CeramicMetal Type: Stainless SteelAppearance: AntiqueFolded: NoSinoarch Shanghai Co., Ltd.5 Yrs Modern Stainless Steel TableUS$ 50 - 250MOQ: 1 SetMaterial: Other, Metal, Glass,Aluminium,CeramicMetal Type: Stainless SteelAppearance: AntiqueFolded: NoSinoarch Shanghai Co., Ltd.5 Yrs

Modern Stainless Steel TableUS$ 50 - 250MOQ: 1 SetMaterial: Other, Metal, Glass,Aluminium,CeramicMetal Type: Stainless SteelAppearance: AntiqueFolded: NoSinoarch Shanghai Co., Ltd.5 Yrs Outdoor Stainless Steel TablesUS$ 50 - 250MOQ: 1 SetMaterial: Other, Metal, Glass,Aluminium,CeramicMetal Type: Stainless SteelAppearance: AntiqueFolded: NoSinoarch Shanghai Co., Ltd.5 Yrs

Outdoor Stainless Steel TablesUS$ 50 - 250MOQ: 1 SetMaterial: Other, Metal, Glass,Aluminium,CeramicMetal Type: Stainless SteelAppearance: AntiqueFolded: NoSinoarch Shanghai Co., Ltd.5 Yrs Stainless Steel Canteen TableUS$ 50 - 250MOQ: 1 SetMaterial: Other, Metal, Glass,Aluminium,CeramicMetal Type: Stainless SteelAppearance: AntiqueFolded: NoSinoarch Shanghai Co., Ltd.5 Yrs

Stainless Steel Canteen TableUS$ 50 - 250MOQ: 1 SetMaterial: Other, Metal, Glass,Aluminium,CeramicMetal Type: Stainless SteelAppearance: AntiqueFolded: NoSinoarch Shanghai Co., Ltd.5 Yrs Stainless Steel Dining TableUS$ 50 - 250MOQ: 1 SetMaterial: Other, Metal, Glass,Aluminium,CeramicMetal Type: Stainless SteelAppearance: AntiqueFolded: NoSinoarch Shanghai Co., Ltd.5 Yrs

Stainless Steel Dining TableUS$ 50 - 250MOQ: 1 SetMaterial: Other, Metal, Glass,Aluminium,CeramicMetal Type: Stainless SteelAppearance: AntiqueFolded: NoSinoarch Shanghai Co., Ltd.5 Yrs